HVAC Steel Sheet Auto Plasma Cutting Machine for Sale

Nanjing Shanduan Cnc Machine Tool Co., Ltd.- Customized:Customized

- Layout:Horizontal

- Cutting Material:Iron, Stainless Steel

- Automatic Grade:Automatic

- Power Source:Electric

- Cutting Mode:Plasma Cutting

Base Info

- Transport Package:Standrad

- Trademark:YSDCNC

- Origin:Nanjing

- HS Code:8456401000

- Production Capacity:600sets

Description

Basic Info.

Transport Package Standrad Trademark YSDCNC Origin Nanjing HS Code 8456401000 Production Capacity 600setsProduct Description

hvac steel sheet auto plasma cutting machine for sale

plasma cutting machine

YSD duct production machines are: automatic duct production line, CNC Angle steel flange production line, double (single)linkage TDF flange machine, Angle code mould, plasma cutting machine, seven functions locking machine, manual( pneumatic )crimping machine, five lines (seven lines) beading machine, Angle crimping machine, reel shear beading machine ,leveling bending machine,steel-bend type,horizontal shrimp bend machine,pneumatic joint machine,Angle setter,bias samsung rolling machine.

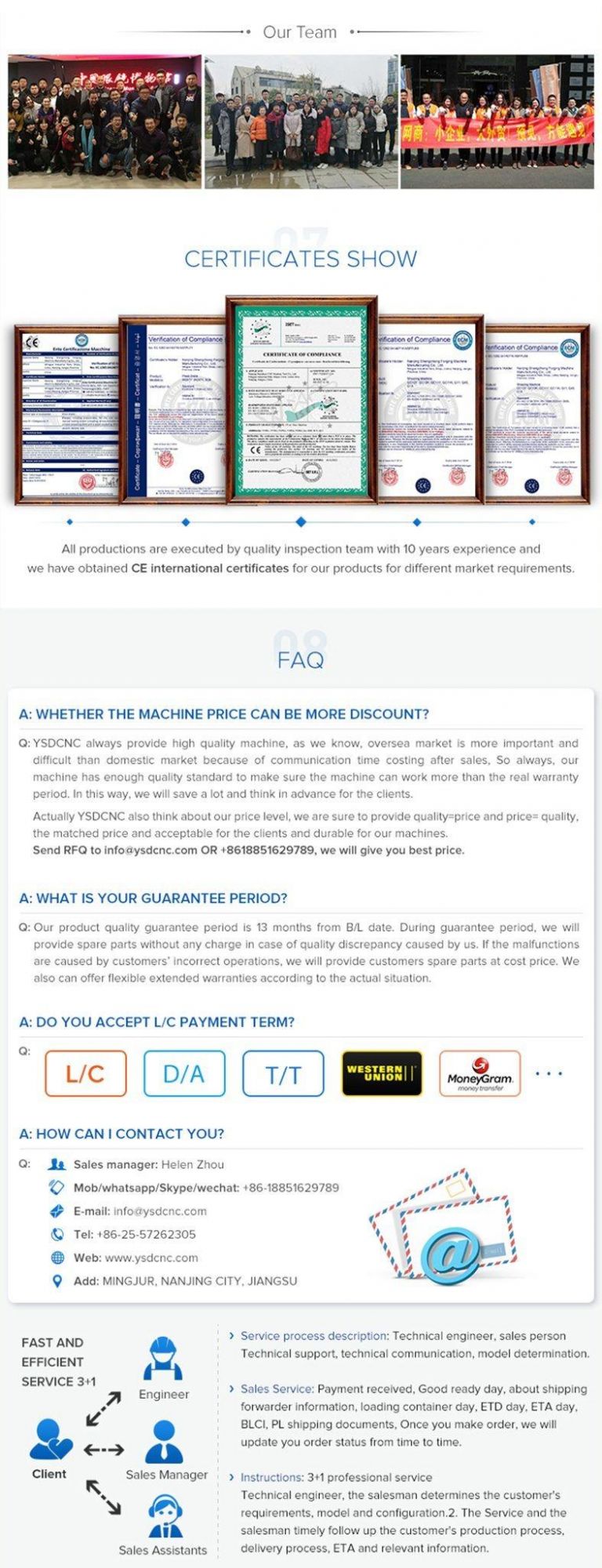

| Company Name (manufacturer): Nanjing Shanduan CNC Machine Tool Co., Ltd. |

| Brand: YSDCNC |

| Address: MINGJUR INDUSTRIAL CONCENTRATION DISTRICT,SHIQIU TOWN,LISHUI AREA,NANJING,JIANGSU |

| Tel:+86 025-57262305 Phone:+86 18851629789 |

| Website: www.ysdcnc.com |

Function:

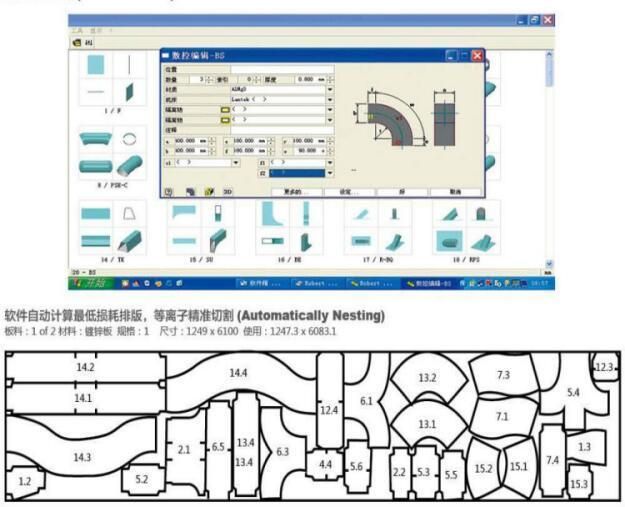

It's mainly for automatically lofting and cutting the deformed workpiece.You can select a drawing from the new version of CAM-DUCT and input dimensions and choose a way of connection,then the software will start calculating,composing,jacking and cutting automatically according to your requirements.

Performance Features:

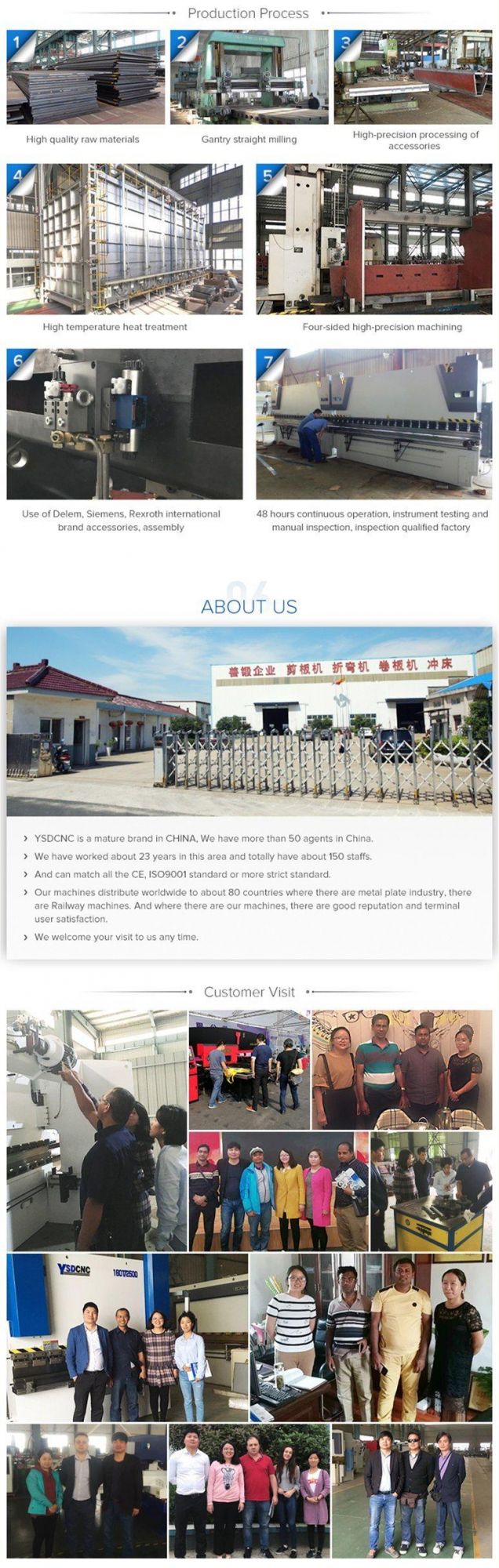

The machine is desktop gantry structure with double-side drive. X & Y axes track are precise cylindrical linear guide rails, precise gear and rack drive, runs stably.Machine frame adopts the whole welding and annealing treatment, main frame is made by medium-sized steel pipe through welding; rail base plates are made through the planer precision processing, high strength, good precision and no deformation.

Crossbeam, side panels and all movable parts are made by aluminum alloy through fine casing and milling, with features of high strength and small inertia, ensuring the high strength and avoiding the cutting positioning instability caused by high inertia.

Adopting HP105 portable arc-pressure height regulator which can automatically regulates the height between cutter and plate to ensure the cutting quality. Scientific structure can effectively avoid collision between cutting head and steel plates owning to reaction rate cannot matches with that of cutting head.

Software:

The machine adopts the latest CAM-DUCT software from Auto Desk company and the software combines technology,data procedure with management and meets cutting requirements of duct workplace by using pre-designed standard duct drawings and parameter settings.The software is easy to learn and operate because it only requires machine dimensions to develop an unfolded view of deformed duct automatically.

2.CNC Programme PLC controller screen:

Name | parameters | unit |

| Processing area | 1500*3000 | |

| Processing materials | Iron, aluminum, galvanized sheet,white sheet, titanium plate | mm |

Processing thickness | 0.1-4mm | mm |

| Cutting speed | 0-8000mm/min | |

| Input voltage | 380V/50hz/3ph or other | V |

Plasma current | 63 (Chengdu Huayuan Brand) | A |

Control system | SF-2012AH (camduct software) | |

| File transfer mode | USB interface | |

work | Non-contact arc | |

Reposition precision | ±0.05mm | |

Processing precision | ±0.1mm | |

| dimension | 3800*2200*1500 mm |

plasma cutting machine