Precision Metal Aluminum Plastic CNC Machined Motorcycle Auto Spare Parts CNC Tunning Milling Welding CNC Machining Parts

Linyi Hongsheng Foundry Co., Ltd.- After-sales Service:OEM

- Warranty:OEM

- Condition:New

- Certification:CE, RoHS, GS

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

Base Info

- Model NO.:OEM

- Material:Stainless Steel

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

- Transport Package:Bubble File+Cardboad Box

- Specification:OEM

- Trademark:Hongsheng

- Origin:China

- HS Code:8466939000

- Production Capacity:10000 Pieces Per Month

Description

Material: Stainless Steel 304

Tolerance: ±0.001mm

Surface treatment: Electroless plating, Plating, anodizing etc

Processing technology: Precision Turn-milling Complex Machining

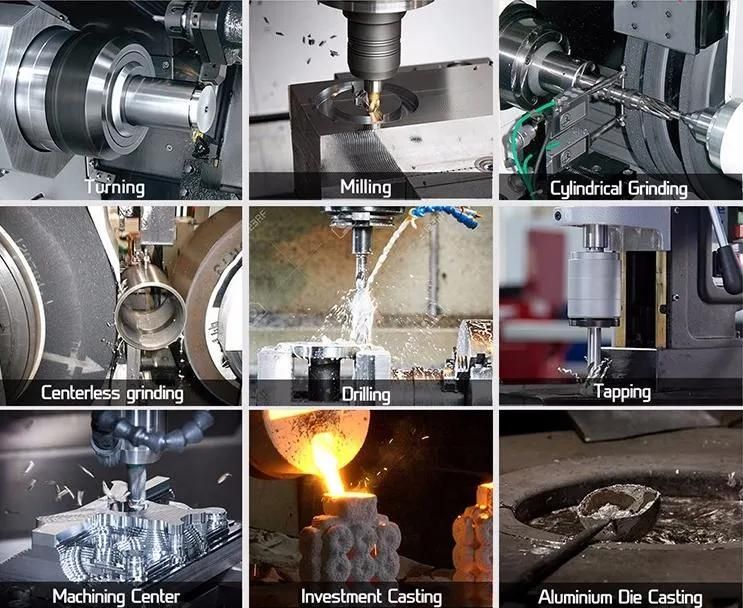

Capabilities: We have the knowledge, experience, and equipment to perform various types of operations.

These include: Boring, Facing, Parting, Drilling, Knurling, Reaming, Grooving, Threading, Face Milling, Hard Turning, Tapered Turning, Peripheral Milling.

Milling machines are versatile.

They can machine simple two-dimensional toolpaths or complex three-dimensional ones that result in extreme geometries. They can produce simple parts or highly complex ones at rapid rates. These high tolerance machined parts find their way into machines manufactured for industries like aerospace, medical, and electronic.

These machines repeat. This capability allows the manufacture of parts that are consistently within a specific tolerance range. This ability assures the parts are interchangeable and conform to the customers specifications. This repetitive ability assures that the parts manufactured are what the customer desires.

These machines allow for a mixture of high or low volume production runs. With modern part fixturing the machines can be left to produce the same part for days or quickly changed hourly to produce short volume production runs.

Milling machines produce precision parts and rapid rates. This volume of production allows the creation of the products that we use in the modern world at affordable prices.

Lathes, or turning machines, are also controlled with computers. Like mills, they rapidly produce high tolerance machined parts at high rates of production. These machines efficiently remove material to produce cylindrical parts. The most commonly recognized examples are nuts and bolts. Cams, bars, and other types of parts are most efficiently manufactured with a turning center.

On many precision parts it is common to use both milling and turning machines to efficiently create the desired geometry.

Company Profile:

Linyi Hongsheng Foundry Co.,Ltd located in Shandong Province, China.

We specialized in silica sol investment casting+CNC Machining with more than 20 years and covers 100,000 square meters

with 500 employees.

Our production management and quality control system fully meet the request of ISO 9001:2015, certified by TUV Rheinland.

Hongsheng Produces a wide variety of high-grade precision casting and machined parts in stainless steel, carbon steel, alloy steel..the main fields including high-speed rail, automobile industry, marine equipment, medical instrument,

machinery parts, construction hardware, pump and valve parts...etc

Other Production Process

Q1: What is our payment term?

A:T/T, Paypal.

Q2: How can we quote for you?

A: Please email us enquiry with all technical drawings you have, such as material grade, tolerance, mechanical

properties, heat treatment, requirements, etc. Our specialized engineers will check and quote for you within 24 hours.

Q3: Which product are often processed by your company ?

A: Auto parts,machinery part, marine part, Kitchen parts, Agricultural parts.

Q4: Which material are often used ?

A: Stainless steel. alloy steel, carbon steel, aluminum, copper.

Q5: Which finish you can provide ?

A:Sand blasting, Tumbling, Polishinh, Electro-polishing, Mirror Polishing, Powder coating, Electrophoresis, ETC.

Q6: What is the MOQ ?

A: Based on the product, normal 100 pcs.

Q7: Can we make the samples?

A: Is Available, 3-7 days for sampling.

Q8: How about for the lead time?

A: Normally about 15-20 days for mass production, pls inform us if it is urgent order.