Yx13.5-137.5-1100/Yx38-190-950 Dual Metal Roll Former

Xiamen Erudite Machinery Co., Ltd.- After-sales Service:One Year

- Type:Rolling Machine

- Forging Forming Method:Cold Roll Forming

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Certification:CE

Base Info

- Model NO.:YX13.5-137.5-1100,YX38-190-950

- Warranty:12 Months

- Customized:Customized

- Advantage:Work Flexible

- Condition:New

- Transport Package:Container

- Trademark:ERUDITE

- Origin:China

- HS Code:8455229090

Description

Basic Info.

Model NO. YX13.5-137.5-1100/YX38-190-950 Warranty 12 Months Customized Customized Advantage Work Flexible Condition New Transport Package Container Trademark ERUDITE Origin China HS Code 8455229090Product Description

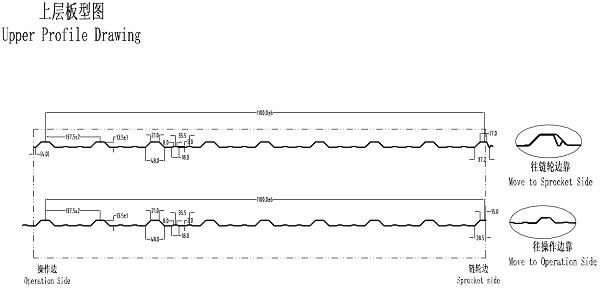

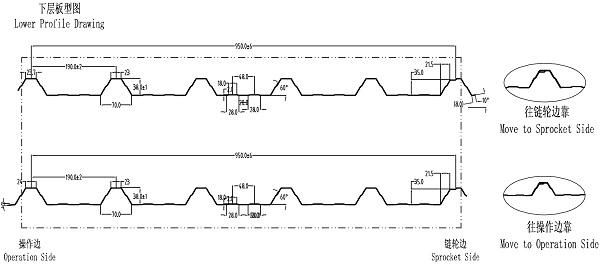

YX13.5-137.5-1100/YX38-190-950 Dual Metal Roll Forming LineProfile:

The Chart of Process Flow

Machine Components

Un-coiler

There are different choices, please turn to the catalogue of un-coiler

Manual pre-shearing Device (Un-powered)

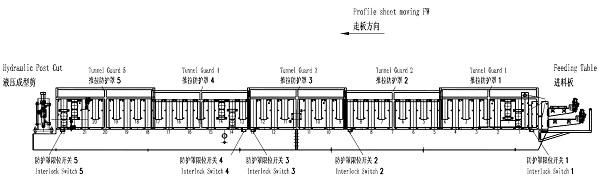

Dual Roll Forming Machine

Feeding section with guide

Polythene film on device, un-power

Gear/Sprocket driving; Dual Level

Upper Level for profile, YX13.5-137.5-1100, 21stages to form

Lower Level for profile YX38-190-950, 22stages to form

Rollers manufactured from 45# steel with forge treatment, CNC lathes, hard Chrome Coated

Shafts Diameter=ф75/95mm, Precision Machined

Main motor =11 KW, Frequency speed control

The two levels can't be run at the same time

Max. Line speed of roll former: 25 m/min

Hydraulic Cutting Device

Stop to cut, Post cut, No Blanking cut

Two pairs of cutting tools, one forYX13.5-137.5-1100,another for YX38-190-950

Cutting tool material: Cr12, Heat treatment

Hydraulic group, Pump motor =7.5KW

PLC Control System

Control the quantity & cutting length automatically;

Control the switch action to run the different two profiles

Combined with:

PLC, Touch Screen: Siemens

Inverter: Siemens or Schneider or Shihlin

Encoder: Omron

Cut-to-length tolerance≤±2 mm

Control Voltage 24V

Run Out Table

Unpowered rack, with height adjustable

Or Motorize Stacker as an option

Packing Method:

Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),

loaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.

Xiamen Erudite Machinery Co., Ltd is a professional manufacturer specializing in the design and production of roll forming machines and bending/curving machines to serve the metal building industry.

Before the inception of its establishment, Erudite invested and set up its own R & D team to enhance the technologies in design, production and quality control. Erudite has experienced engineers and technicians who have worked in this field of business for over 10 years individually. Erudite can provide customized, accurate and comprehensive design for machinery according to the clients' profile drawings and technical requirements. Erudite has actively invested in research and development, obtained a number of patents, and has been selected as a National High-tech Enterprise in 2021.Erudite equipped with professional production technical management personnel, supporting series supply chain services from design, production, and technical support to after-service. The professional sales team in Erudite is responsible for providing professional recommendation and solutions to clients before sales and after sales to ensure our customers can maximize their investment and meet their production requirements/demands with a fruitful return on investment.

Erudite is willing to be your sincere and trustworthy partner!