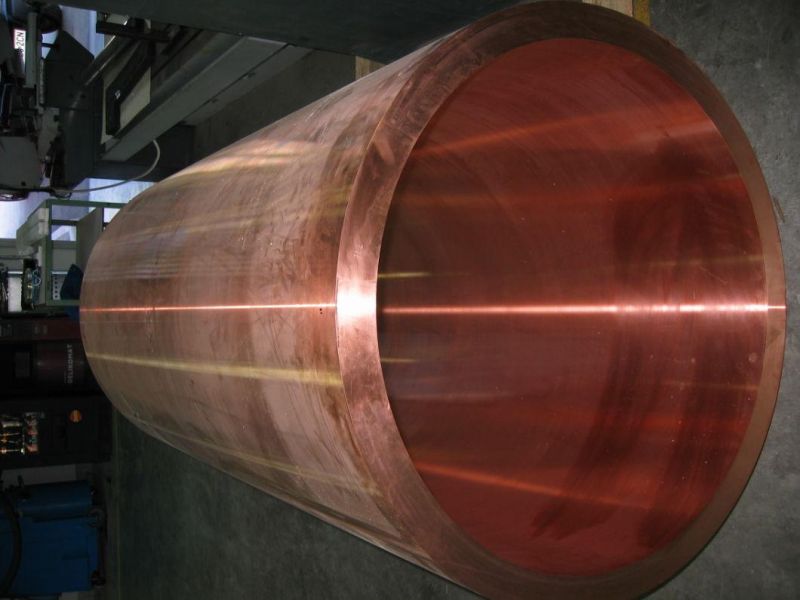

Copper Alloy Cast Roller Sleeve for Aluminium Mill

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Application Range:Metal Rolling

- Transport Package:Woodern Case

- Trademark:FANGLE

- Origin:China

- HS Code:8455300000

- Production Capacity:15000tons,Year

Description

Basic Info.

Application Range Metal Rolling Transport Package Woodern Case Trademark FANGLE Origin China HS Code 8455300000 Production Capacity 15000tons/YearProduct Description

Copper Alloy Cast Roller Sleeve

Brief Discription:

Copper Alloy Cast Roll Shell has high thermal crack and fatigue resistance,typical productivity improvement for the use of combination Copper/Steel shells is around 40 to 60%, and for Copper/Copper shells is about 70 -110%,with the large productivity improvements, there is an overall economic benefit of copper shell production even considering the higher cost of the copper shell.

Technical Parameters:

Chemical Composition %

| Be | Ni+Co | Si | others |

| 0.25-0.50 | 1.00-1.70 | 0.05-0.30 | ≤0.10 |

Physical Properties (20ºC)

| Tensile Strength | Yield Strength | Elongation | Hardness | Conductivity |

| ≥630MPa | ≥510MPa | ≥10% | ≥220HB | ≥60%IACS |

Productivity Comparison

| Shell Combination | Strip Gauge (mm) | Casting Speed (m/min) |

| Steel/Steel | 5-10 | 0.4-1.1 |

| Copper/Steel | 5-10 | 1.2-1.65 |

| Copper/Copper | 5-10 | 1.3-2.4 |

Product Show:

Customers Visiting:

Our customers spread all over Germany, Slovenia, Italy, Russia, UAE, KZ, Iran, Brazil, Mexico, Northe America, Korea, Indonesia, etc.