PVD Vacuum Coating Installation for Glass, Bathroom, Ss, Ceramic, Jewelry

Ningbo Danko Vacuum Technology Co., Ltd.- Type:Arc & Sputtering Discharge

- Coating:Vacuum Coating

- Substrate:Metal, Steel, Glass, Plastic, Ceramic

- Certification:CE, ISO, TUV

- Condition:New

- Application:Tile Gold Film Vacuum Plating Machine

Base Info

- Model NO.:DK

- Driven Type:Electric

- Voltage:220V, 380V, Customized Definition

- Chamber Materials:SUS 304

- Service:24h, Remote Guidance

- Control System:Automatic, Manual, PLC

- Structure Type:Vertical Type

- Machine Type:PVD Machine

- Accessories:Pumps, Targets, Power Supply Available

- Warranty:at Least One Year

- Transport Package:Wood Case, Container

- Specification:1600*1500mm

- Trademark:Danko

- Origin:Ningbo, China

- HS Code:8479899990

- Production Capacity:1000sets,Year

Description

Basic Info.

Model NO. DK Driven Type Electric Voltage 220V, 380V, Customized Definition Chamber Materials SUS 304 Service 24h, Remote Guidance Control System Automatic, Manual, PLC Structure Type Vertical Type Machine Type PVD Machine Accessories Pumps, Targets, Power Supply Available Warranty at Least One Year Transport Package Wood Case, Container Specification 1600*1500mm Trademark Danko Origin Ningbo, China HS Code 8479899990 Production Capacity 1000sets/YearProduct Description

PVD Vacuum Coating Installation for Glass, Bathroom, Ss, Ceramic, Jewelry[PVD]

Physical Vapor Deposition: Vacuum deposition methods which can be used to deposit thin films and coatings.

Description

Multi-arc Ion Sputtering Coating Machine is high performing and easy operating, equipped with arc sputtering system.

Substrate Material: Glass, Metal, Ceramics Glass, Metal (carbon steel, stainless steel, brass), Ceramics, Plastic, jewelry.

Recommend Machine: Multi Arc Magnetron Sputtering Plating Machine

Structure Type: Vertical structure, #304 Stainless Steel

A. Coating Film: Multi-functional metal film, composite film, transparent conductive film, reflectance-increasing film, electromagnetic shielding film, decorative film

B. Film Color: gold, rose gold, silver, colorful, sapphire blue, gun black, brown, dark black, etc

C. Film type: TiN, CrN, ZrN, TiCN, TiCrN, TiNC, TiALN and DLC

D. Consumables in production: Titanium, Chromium, Zirconium

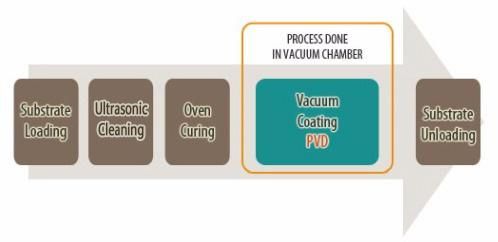

Process

Application

A. Watch industry, such as watch belt, watchcase, dial etc.

B. Hardware, such as sanitary ware, door handle, door locks

C. Construction industry, such as stainless steel plate, stair handrail, columns

D. Phone shell, parts

E. Jewelry, eyeglasses frame

F. Glassware, such as glass cup, glass lamps, glass artworks

G. Table wares, like metal forks and knives.

H. Golf wares, like golf head, golf pole and golf balls.

I. Sanitary Products/bathroom wares

J. Large size sheet, plate, pipe, tube and so on. Like large stainless steel plate and furnitures.

Advantages

A. Pumps:

Mechanical pump + roots pump + diffusion pump + holding pump (or optional: cryogenic pump, cryogenic pump system)

B. Gas System: 1-4 path

C. Limited Vacuum: 6*10-4 pa (cleanroom, no-loading)

D. Targets: arc 6-18sets, magnetron target 1-2sets

E. Power Sources: DC power supply, Medium frequency power supply, medium frequency power supply, heater supply, activation power supply, pulsed bias voltage power supply

F. Targets: DC Magnetic Target, Medium Twin Target, Plane Target

H. Gas Time : 5*10-4 pa, within 30mins

I. Controlled by Manual, Semi-automatic, Full automatic, PLC

Workshop

For more details on configurations quotations, please contact us.

Ningbo Danko Vacuum Technology Co.,Ltd

https://dankovac.en.made-in-china.com

Sara