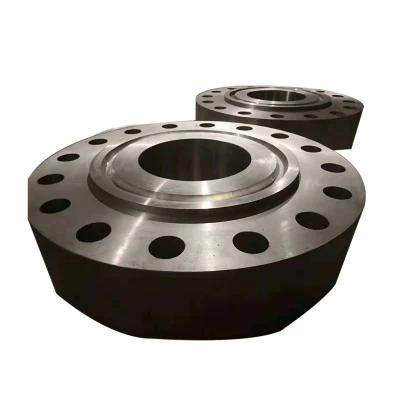

Manufacturer OEM Alloy Forged Steel Hot Forging Products for Shaft/Roll/Ball/Gear/Ring

HENAN QIANGXIN PRECISION MACHINERY CO., LTD.- Condition:New

- Certification:CE, RoHS, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

- Material:Alloy

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Model NO.:OEM

- Transport Package:Pallet

- Specification:Customized

- Trademark:Qiangxin

- Origin:Xinxiang City, Henan Province, China

- HS Code:7307190000

- Production Capacity:200ton-1500ton Per Month

Description

Basic Info.

Model NO. OEM Transport Package Pallet Specification Customized Trademark Qiangxin Origin Xinxiang City, Henan Province, China HS Code 7307190000 Production Capacity 200ton-1500ton Per MonthProduct Description

Manufacturer OEM Alloy Forged Steel Hot Forging Products for Shaft/Roll/Ball/Gear/Ring

Factory

Inspection

Certifications

| Process | Hot forging, die forging and Free forging |

| Material | Carbon steel: 1020,1020,1035,1045,1055,Q235,Q345 etc., Alloy steel: 40Cr, 20CrMnTi, 20CrNiMo,35CrMn,42CrMo4 etc., Stainless steel, SS304,SS316 etc. Aluminum |

| Standard | ISO, DIN, ASTM, BS ect. |

| Weight | 0.1kg - 120kg |

| Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc. |

| Machining Tolerance | 0.02mm-0.1mm |

| Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

| Applicable Heat Treatment | Normalization , quenching and tempering, Cas Hardening, Nitriding, Carbon Nitriding, |

| Applicable Finish Surface Treatment | Shot/sand blast, polishing, Surface passivation, Powder coating, E- Coating, Chromate Plating, zinc-plate, Dacromat, Painting, |

| Testing equipment | Supersonic inspection machine, Supersonic flaw detecting machine , physics and chemical analysis. |

FAQ

Q: What do I need for offering a quote ?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.) ,quantity, application or samples. Then we will quote the best price within 24h.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers' requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, L/C, Escrow, paypal, western union, moneygram etc.

Q: Is it possible to know how is myproduct going on without visiting your company?

A: We will offer a detailed products sched