Metal Plate Guillotine Shear Knife for Cutting Iron Carbon Stainless Steel Aluminum

Jiangsu Xinmechan Technology Co., Ltd.- Warranty:1 Month

- Condition:New

Base Info

- Certification:CE, ISO9001

- Standard:ASTM, GB

- Customized:Customized

- Material:T10, 9crs, 6crw2si, Cr12MOV, H13, Alloy etc

- Application:Metal Cutting Machine, Metal Processing Machinery Parts, Metal Plate Shearing Guillotine Machine

- Type:Metal Sheet Shearing Guillotine Tool Knife

- Coating:Titanium Coating or by Custom

- Application Material:Steel Bar,Stainless Steel,Carbon Steel,Aluminum

- Dimension:by Custom

- Drawing Format:Ai, Psd, Pdf, JPG etc

- Transport Package:Wood Case

- Specification:by custom

- Trademark:XINMECHAN

- Origin:China

- HS Code:8208109000

- Production Capacity:20000 PCS,Month

- Package size per unit product:135.00cm * 15.00cm * 5.00cm

- Gross weight per unit product:35.000kg

Description

Basic Info.

Certification CE, ISO9001 Standard ASTM, GB Customized Customized Material T10, 9crs, 6crw2si, Cr12MOV, H13, Alloy etc Application Metal Cutting Machine, Metal Processing Machinery Parts, Metal Plate Shearing Guillotine Machine Type Metal Sheet Shearing Guillotine Tool Knife Coating Titanium Coating or by Custom Application Material Steel Bar,Stainless Steel,Carbon Steel,Aluminum Dimension by Custom Drawing Format Ai, Psd, Pdf, JPG etc Transport Package Wood Case Specification by custom Trademark XINMECHAN Origin China HS Code 8208109000 Production Capacity 20000 PCS/MonthPackaging & Delivery

Package size per unit product 135.00cm * 15.00cm * 5.00cm Gross weight per unit product 35.000kgProduct Description

| Description | Metal Shearing Tool Knife / Blade | Grinding | Sandwheel Grinding 60 Meshes | |

| Blade Material | H13, T10, 9CrS, 6CrW2Si, Cr12MoV, Alloy etc | Blade Edge Grinding Fixture | Fixtures Designed Accoding to Grinding Process | |

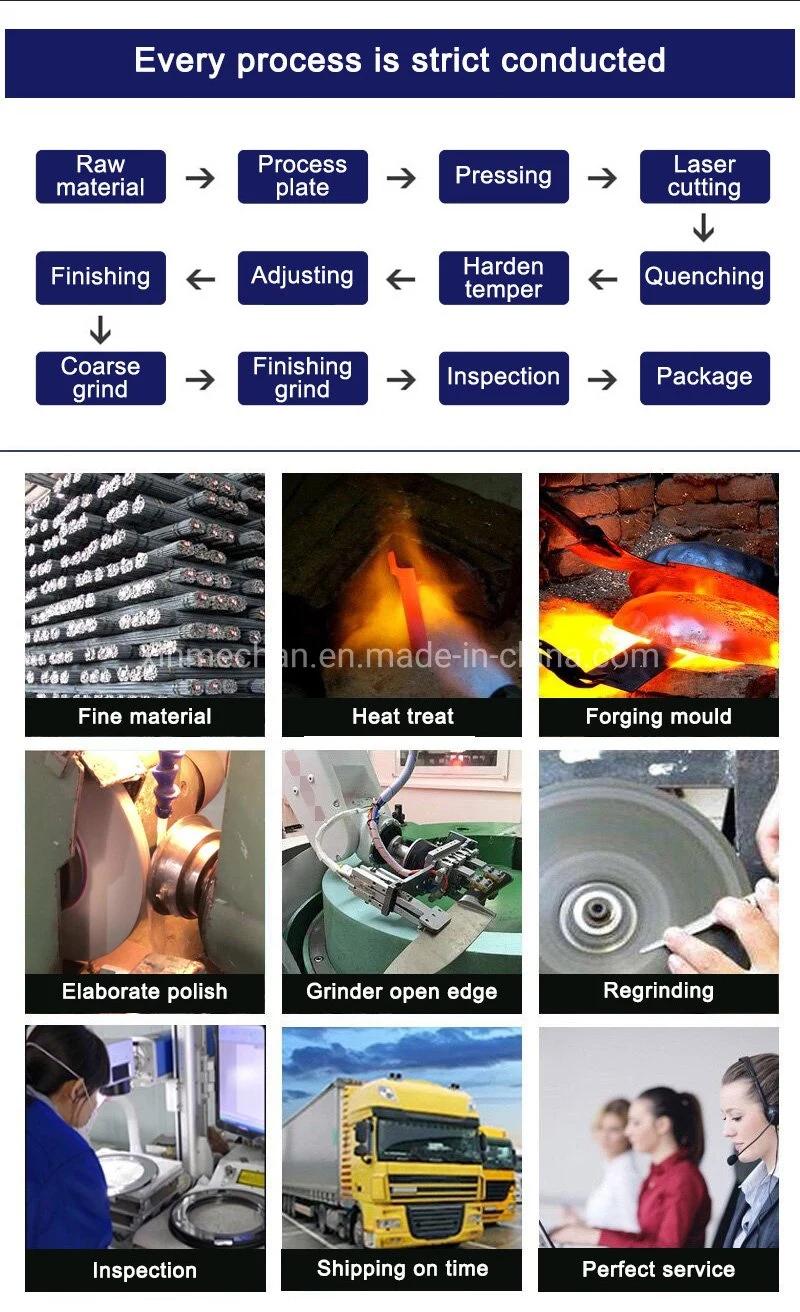

| Application | For Shearing metal etc | Blade Production Process | Raw Material Stamping, Heat Treatment, Fine Grinding etc | |

| Raw Material Process | Laser Cutting / Wire Cutting, Forging or Stamping | Inspection Methods | Callipers or Projector | |

| Heat Treatment Method | High temperature heat treatment | Cutting Ways | Slitting, Shearing, Cutting, Shredding and Pulverizing etc | |

| Shearing Edge Angle | By custom | Transport Package | Wooden box / Carton box | |

| Hardness | 36 to 68 H.R.C | Specification | by standard or by custom | |

| Surface Coating (optional) | Enp, Nickel Plating, Titanium Nitride Plating | Trademark | XINMECHAN or OEM ODM | |

| Blade Precision | -/+0.01mm to -/+0.1mm | Origin | Jiangsu, China | |

| Applications | Metal processing and manufacturing industry etc | Production Capacity | 200000pcs/Month |

Raw Material: T10, 9CrS, 6CrW2Si, Cr12MoV, H13, Alloy etc

Size: support customization

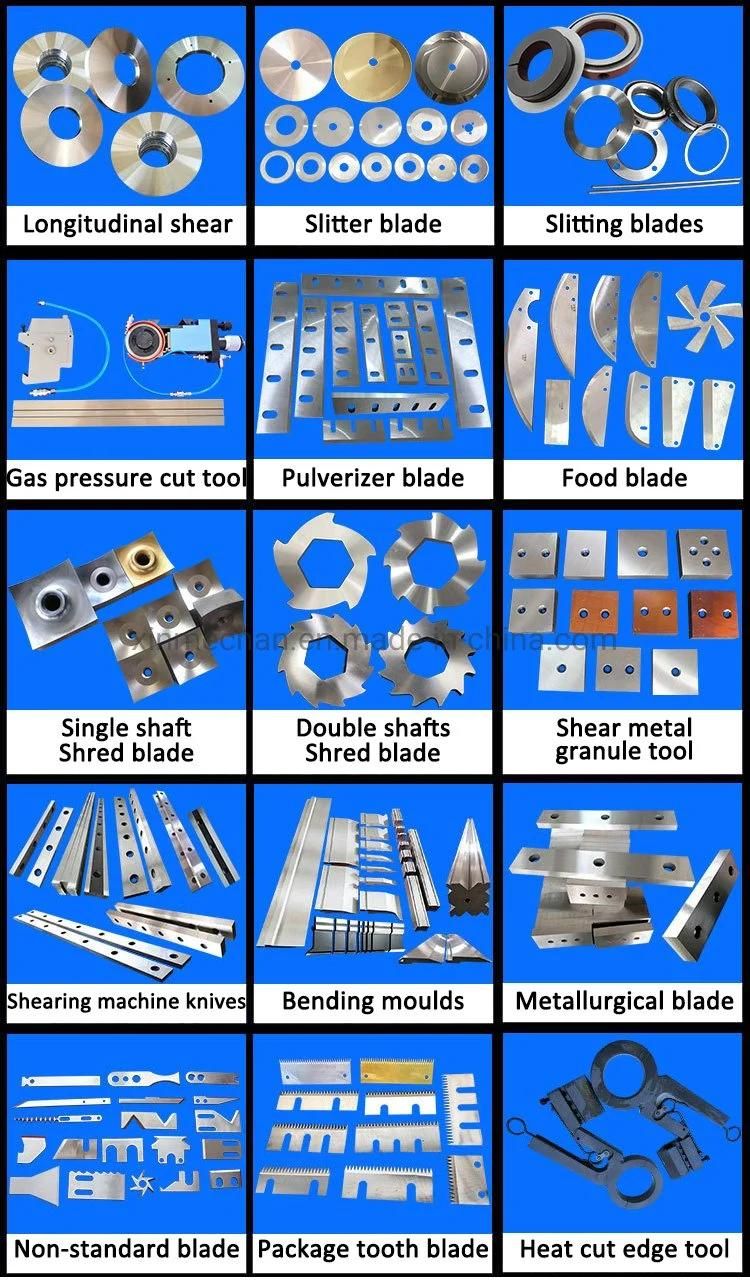

More products we supply

Specification

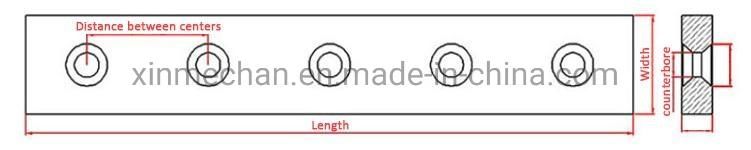

Please send us the tools drawing for accurate shape and size, refer to below picture.

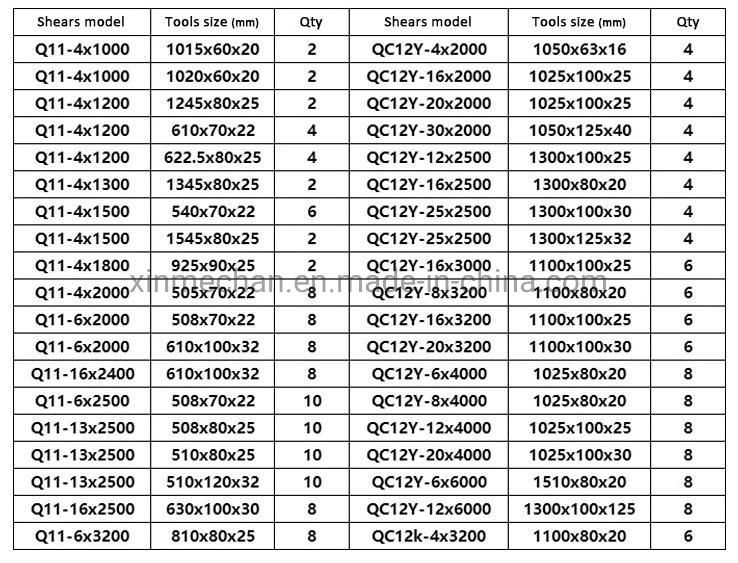

Below parameters are for parts normal models of shearing machines, FYI.

Jiangsu XINMECHAN Technology company is specialized in manufacturing various machinary tooling blades and knives.

With an excellent reputation for professional industrial machines tools blades manufacturer and the persistent innovation in blade material development, we always insist on providing customers with multiple solutions in terms of product research, development, design, usage and sales.

Our company has a factory area of 15,000 square meters. We have also imported advanced equipments, including 4 column hydraulic press, the high vacuum sintering pressurized furnace, ball-grinding mill, throwaway twin-face lapping machines and high precision grinding machines in total 37 sets. The practical measured data of our products is collected by a modern physics laboratory via international standard testing. The actual production of knives and blades is able to reach 2000,000 pieces annually.

For years, we preserver in pursuing top quality and best service. We has established a good reputation in home and abroad. We will still making great efforts on the practice of the business philosophy of honesty, innovation, expansion and aggressiveness, and aim at providing better service to our customers.

We have a group of knowledgeable and professional young team workers who are specialized in different subjects of mechanical industry, committed to serving for our customers. We can supply standard products as well as meet special order requirements of customers and provide an optimum plan for every user.

Monument Strength

We are constantly involving in technique innovation and technical improvement to supply more advanced products for you. We had implemented the international quality system standards fully. Each process of production and delivery is in accordance with the requirements of national and industry standards as well as users need strictly. We can guarantee the products our customers received are of superior quality.

Service

Pre-sales services, supply customization

We provide customers with the best possible process solutions, technical advice, samples to test, model selection and other consulting service.

In-sale services, provide all aspects of technical support

We design tailor-made training programs for you, including equipment operation, product maintenance and maintenance, troubleshooting, safety operation and other aspects of training.

After-sales service perfectly and timely

We guarantee 10 hours to respond to customer demand, free maintenance during the warranty period, life-long maintenance, timely provision of spare parts, remote diagnosis, regular visits and other services.

FAQ

Q1. How to get the most suitable product and best price?Please tell us what you want, the size/dimetnsion, drawing, applied cutting material, raw material and other information. It's better to send us the drawing.

Q2. Can you help to design or draw the blade we need?

Yes, we can, if only you tell me the specific dimension, length, width, thickness, shape, diameter and so on.

Q3: What is your advantage?

A3: 1. End manufacturer with competitive factory price.

2. Different raw materials for you to choose, we can give a professional suggestion to you.

3. Various blades for you to choose, OEM&ODM is supported.

4. High wear resistance and waterproof.

5. Short delivery time & safe packaging.

Q4: How long is your delivery time?

A4: Generally it is 3 days if the goods are in stock. or it is 15-45 days if the goods are not in stock, it is according to

quantity.

Q5: Do you provide samples? Is it free or extra ?

A5: Yes, we could offer the sample. Products below $10 is free charge but freight cost by yourself.