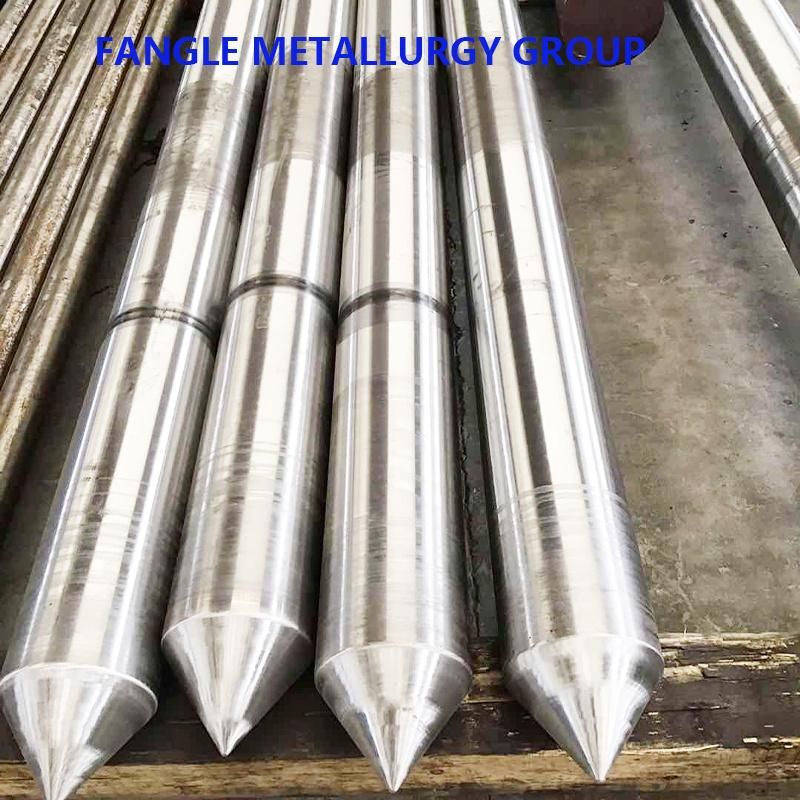

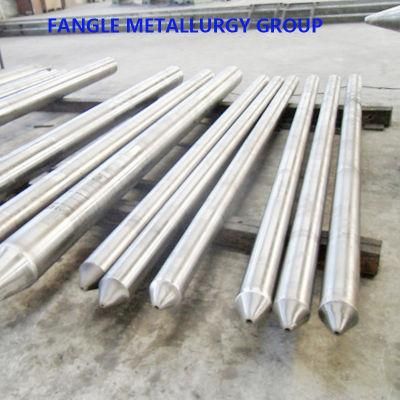

Piercing Mill Mandrel for Hot Rolling Production Line

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as customer requirement

- Application Range:Mpm-Mill, Push Bench, Assel Mill

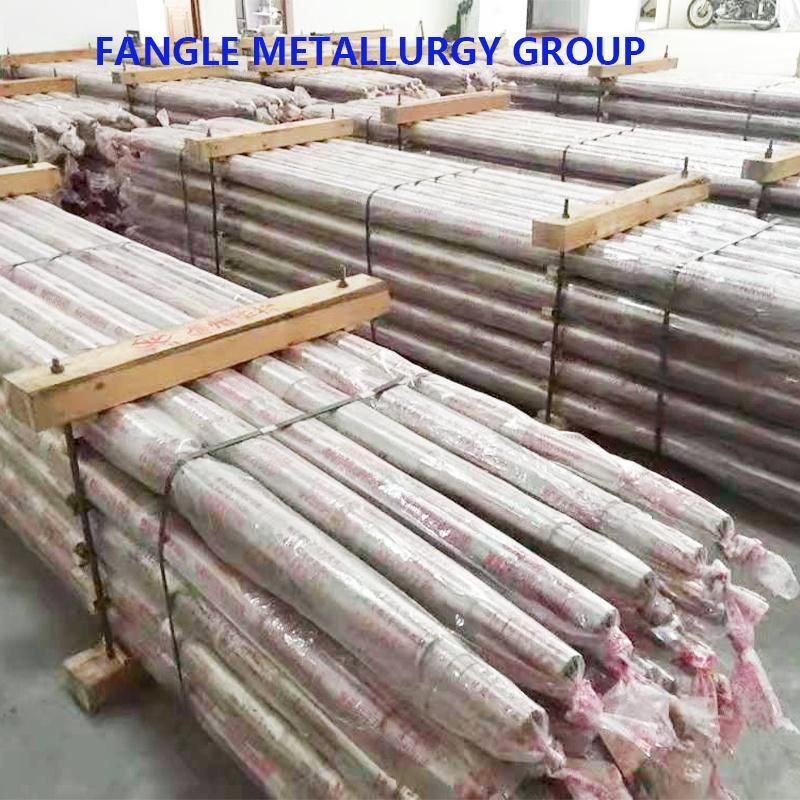

- Transport Package:Woodern Case

- Specification:Export package

- Trademark:FANGLE

- Origin:China

- Production Capacity:10000 Tons,Year

Description

Basic Info.

Model NO. as customer requirement Application Range Mpm-Mill, Push Bench, Assel Mill Transport Package Woodern Case Specification Export package Trademark FANGLE Origin China Production Capacity 10000 Tons/YearProduct Description

Piercing process is the important process in the seamless tube production process. Piercing mandrel is the key part in the piercing process. The working life of piecrcing mandrel directly effects the production cost and production .We can produce piercing mandrel with material H13 (X40CrMoV 5-1/4Cr5MoSiV1), 28NiCrMoV10 (1.2740), X35CrMo V51, 42CrMo, etc, and the size Dia 50-450mm; Length: < 20000 mm.Production process : ·Forging round bar ·Heat treatment ·Finish machining ·Package Quality Assurance : ·MT report ,UT report and Size report will be supplied before shipment .