Customized CNC Lathe Turning Machining Small CNC Turning Stainless Steel Parts

Suzhou Baosheng Precision Technology Co., Ltd.- Condition:New

- Certification:CE, RoHS, GS, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

- Material:Metal

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Factory:Yes

- Logo:Customized Logo

- Size:Customer′s Requst

- Color:as Requirement

- Tolerance:+,-0.01 or Custom

- OEM & ODM:Yes

- Quality Control:100% Inspention

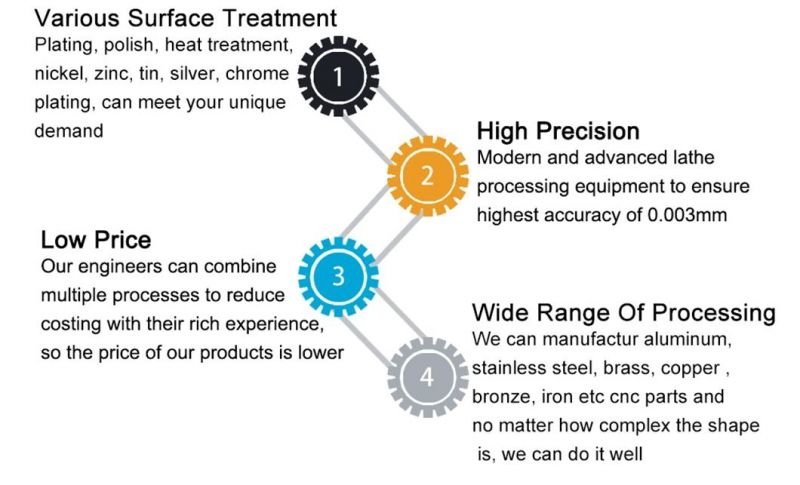

- Advantage:High Precision

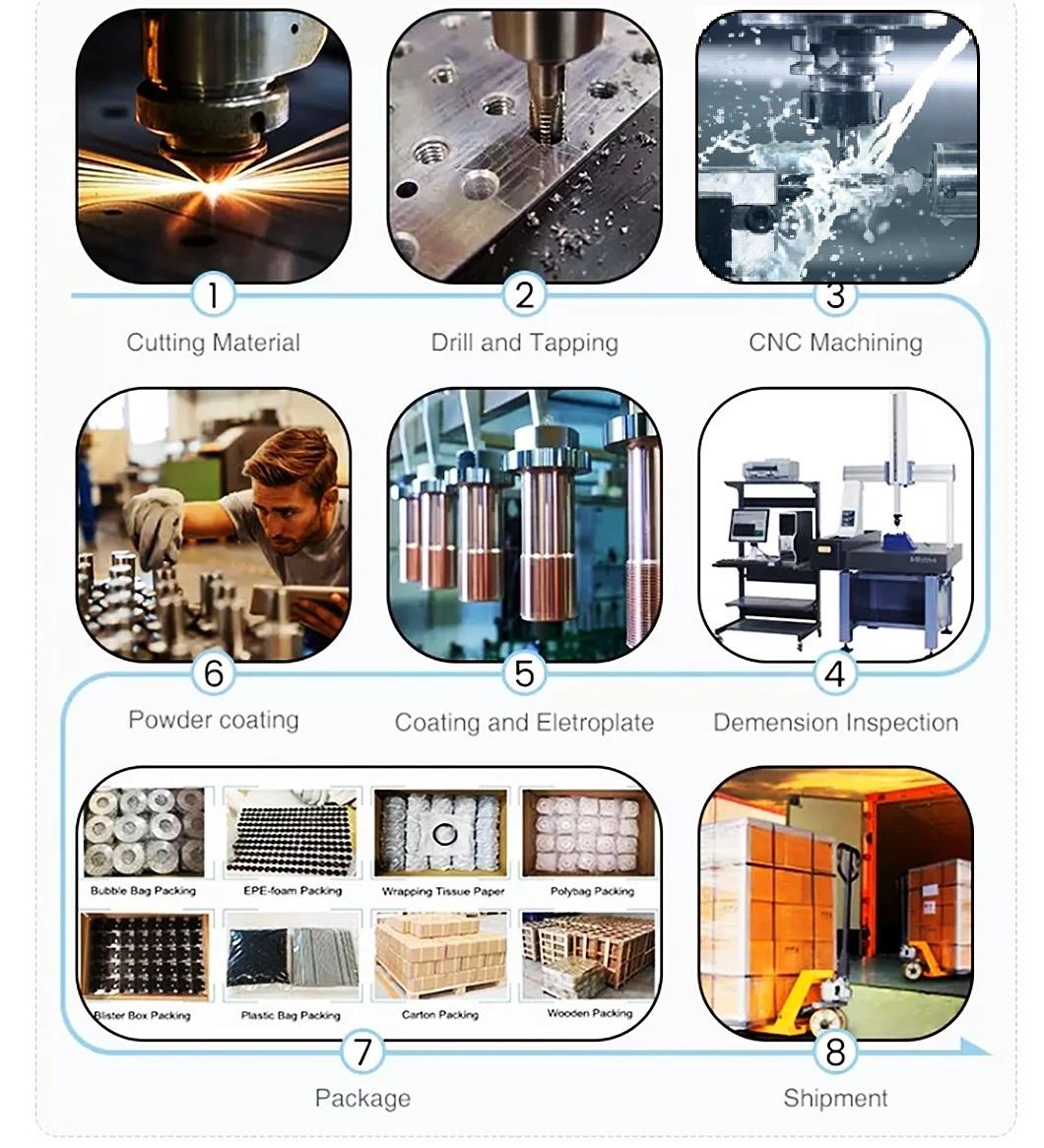

- Transport Package:Wooden Box, Carton, Plastic Box or Customized

- Specification:CUSTOMED

- Trademark:BS

- Origin:Suzhou China

- HS Code:846693900

- Production Capacity:80, 000PCS,Month

Description

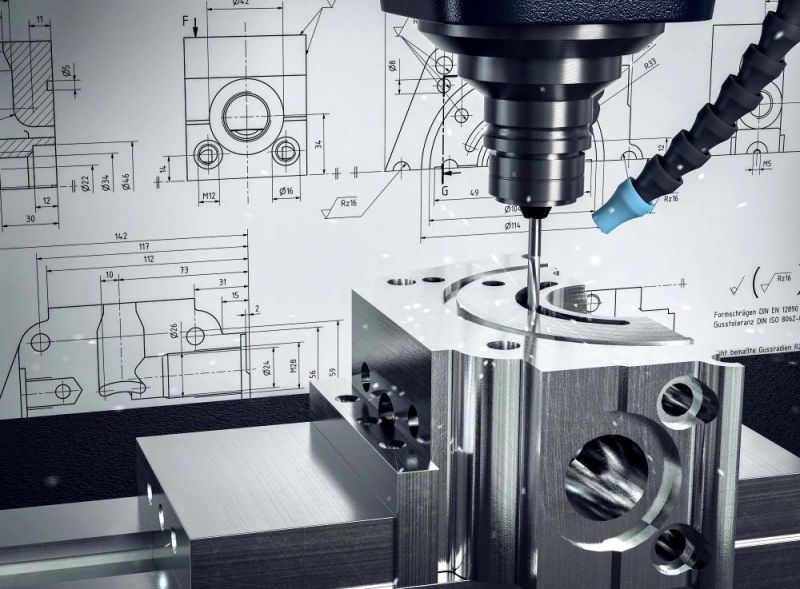

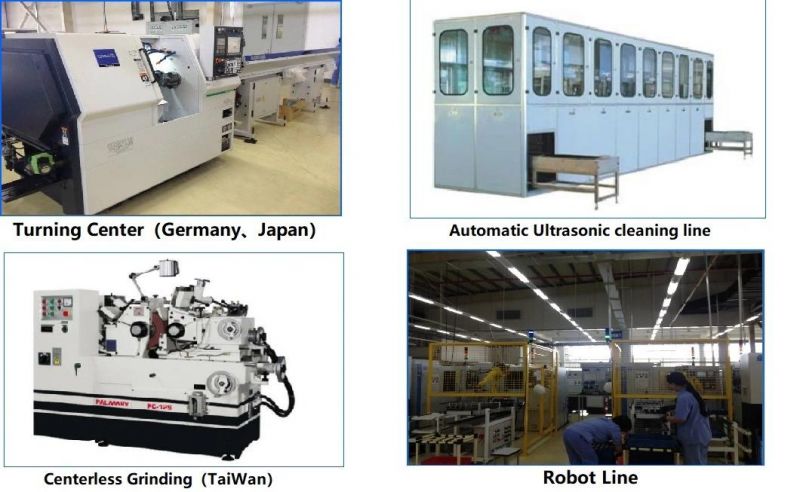

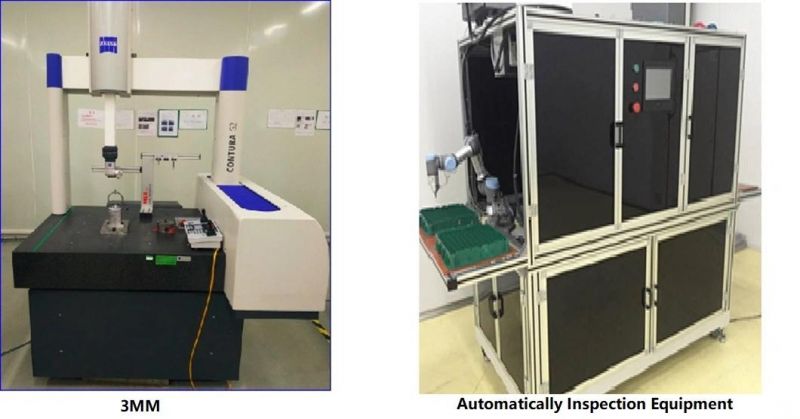

Wujiang Baosheng Precision Hardware Electronics Co., Ltd.Located in fenhu economic development zone, suzhou city, jiangsu province, it is an enterprise specializing in the production and sales of auto engine, new energy auto motor, textile equipment, medical equipment and other industrial parts and supporting components. The company has a strong r & d technical force and first-class production equipment, choose the United States haas, Japan jin shang, Japan Star, Germany DE maggie and Taiwan mingyang and other high-precision CNC turning and milling complex lathe and multi-axis linkage machining center equipment.

In order to create sustainable business opportunities and improve product quality, the company strictly follows iso9001-2008 international quality management system and iatf16949:2016 quality management system for production management; Our company has learned from nearly ten years of manufacturing experience of foreign factories, adhering to the attitude of striving for perfection, and providing customers with high-quality and high-precision hardware parts with professional technical knowledge and perfect after-sales service.

The company was founded in 2006 at the end of the year, the plant covers an area of 5500 . employees 80 people, fixed assets of 50 million yuan. Since its establishment, the company has been seeking for new development ideas, has introduced advanced automation equipment from all over the world, the follow-up will be based on the production demand, all equipped with manipulator, to automatic production as the goal, to create intelligent automation production line, continue to ensure the high precision requirements and consistency of products.

The company's main parts material: 20CR, 40CR, bearing steel, various brands of copper bar, iron, aluminum, stainless steel and other non-ferrous metals, in ten years, has broken through a variety of special material processing difficulties.

2.Maching

2.Maching

3.Cold Forging/Milling/Spline

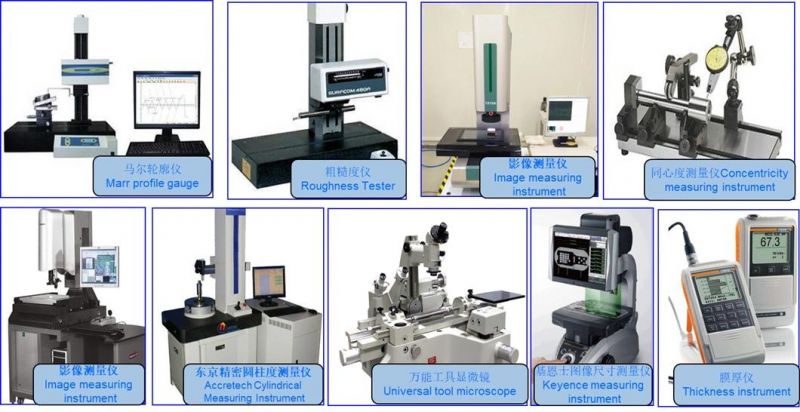

4.Measure

4.Measure 5.Testing

5.Testing

1.How can I get CNC parts sample?

Yes, just need sample cost, we will return it back in mass production.

We also provide free samples in special conditions.

2.How about the lead time?

It depends on quantity, generally 7-20 days after order confirmation.

3.Can you give me help if my products are very urgent?

Yes, we will try our best to give you help. Because we have our own factory to produce. We can flexible to adjust our production schedule.

4.I want to keep our design in secret, can we sign NDA?

Sure, we will not display any customers' design or show to other people, we can sign NDA.

5.Can we know the production process without visiting the factory?

We will offer a detailed production schedule and send pictures and videos which show the machining progress.