Automatic Hydraulic Steel Rebar Screw Forming Thread Rolling Machine with Blade and Coupler

Henan Yugong Machinery Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:High Efficiency

- Certification:CCC, ISO9001, CE

- Warranty:24 Months

Base Info

- Model NO.:YG-40

- Customized:Non-Customized

- Advantage:Work Flexible

- Condition:New

- Production Name:Reinforceing Steel Re-Bar Thread Rolling Machine

- Model:Yg-40

- Rebar Diameter:14-40mm

- Motor Power:5.5kw

- Voltage:380V,50Hz Three Phase

- Spindle Speed:40-62r,Min

- Working Effiency:30-40mm,Min

- Max Thread Length:80mm

- Weight:450kg

- Dimension:1500*600*1000mm

- Coupler Pitch:2.0,2.5,3.0,3.5mm

- Coupler Threading Angle:60,75 Degree

- Peeling Blade:Size Customized

- Rolling Wheel:Inventoru Stock

- Transport Package:Wooden Case Package

- Specification:1500*600*1000mm

- Trademark:Yugong

- Origin:China, Henan

- HS Code:8479819000

- Production Capacity:2000,Month

Description

Basic Info.

Model NO. YG-40 Customized Non-Customized Advantage Work Flexible Condition New Production Name Reinforceing Steel Re-Bar Thread Rolling Machine Model Yg-40 Rebar Diameter 14-40mm Motor Power 5.5kw Voltage 380V/50Hz Three Phase Spindle Speed 40-62r/Min Working Effiency 30-40mm/Min Max Thread Length 80mm Weight 450kg Dimension 1500*600*1000mm Coupler Pitch 2.0/2.5/3.0/3.5mm Coupler Threading Angle 60/75 Degree Peeling Blade Size Customized Rolling Wheel Inventoru Stock Transport Package Wooden Case Package Specification 1500*600*1000mm Trademark Yugong Origin China, Henan HS Code 8479819000 Production Capacity 2000/MonthProduct Description

Steel Rebar Screw Thread Rolling MachineCarbon Steel Sleeve Couplers/Peeling Blades/Rooling wheels

Product Description

Rebar Thread Rolling Machine is mainly used in the construction of ribbed steel bar straight screw thread processing, is to achieve reinforced straight thread connection process of key equipment.

Steel bar straight thread strip ribbed rolling machine, the end of the steel bar into strip ribbed rolling forming. The operation is simple, the quality is reliable, and can realize according to the diameter and length of the adjustment to stop, reverse back. The machine adopts internal water structure, which has better cooling and lubrication effect. Processing of a certain specification of steel as long as the adjustment of good equipment, can be continuously processed.

Mainly used in concrete structure Ф 14 to 40 mm high grade steel straight thread end processing. It has the advantages of simple operation, quick operation, no flame, no pollution and all-weather construction.

Rebar Thread Rolling Machine consists of frame, clamp, rib-peeling head,thread rolling head,reducer, feed and control, electrics,cooling system, etc.The specific structure is shown in the attached configuration diagram, the parts configuration diagram and the wiring diagram.

Technical Parameters

| Model | YG-40 |

| Rebar diameter | 16-40mm |

| Motor power | 4kw |

| Voltage | 3-380V 50HZ |

| Speed | 40-62r/min |

| Max.thread length | 80mm |

| Thread angle | 60°,75° |

| Working efficiency | 30-40mm/min |

| Dimension | 1500*600*1000mm |

| weight | 450kg |

Working process of rebar thread rolling machine

1.Strip rebar rib first.

2. Roll parallel thread on rebar end.

3.Splice two pieces of threaded rebar with coupler.

The Relative Parts of Steel Rebar Threading Rolling Machine

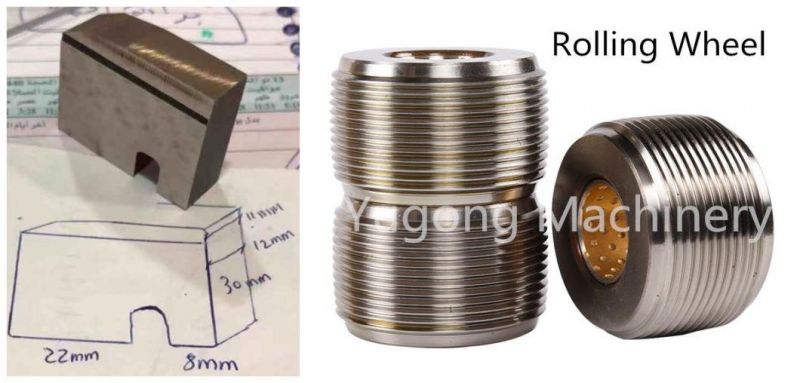

Carbon Steel Sleeve Couplers

Coupler with Customized Threading Pitch/Angle

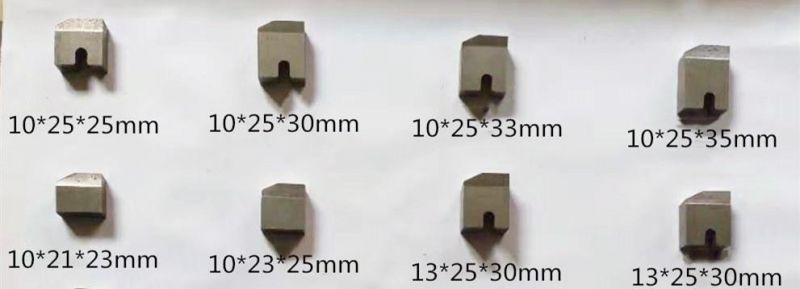

Peeling Blades can be customized various sizes

Packaging and Delivery

1, Packed by standard import&export wooden cases or carton boxes;

2, Customized packaging according to your requirement.

Lead-time: 3-5 working days.

Shipping

Shipping Method: By Logistics, Automobile, Train, Sea, Air.

Port: Tianjin, Qingdao, Shanghai or others port.

Our Service

Pre-sale Service:

A, Timely/Prompt response to customer;s inquire.

B, Smooth/Professional Communication with customer on the technical parameters details of product.

C, Recommend the suitable products and relative products and Technical support according to customers information and requirements.

After-sales Service:

A, Warranty 2 years

B, Technical Support - installation instruction, telephone/video technical instruction.

C, Extra Accessories Provided Free of Charge