Automatic Plating Line Electro Zinc Line Barrel Plating Line/Equipment Price

Junan Tongda Electronic Equipment Factory- After-sales Service:Yes

- Voltage:380V

- Automatic Grade:Automatic

- Warranty:1 Year

- Certification:CE, ISO

- Material:15mm PP,PVC

Base Info

- Model NO.:TD-B

- Machine Type:Automatic Type,Semi Automatic Type

- Coating:Zinc ,Nickel,Copper,Chrome,Gold Coating

- Around Machine:Filter,Chiller,Rectifier

- Manufacturer:Yes

- Customized:Yes

- After Sales Service:Online Supports

- Service:Longlife Technology Support

- Application:on Nails, Bolts, Bullets etc

- Main Parts:PP ,PVC Tank.Crane

- Plating Style:Barrel Type

- Electroplating Style:Cool Plating

- Product Name:Zinc Plating Machine

- Transport Package:Plywood Box

- Specification:Customized

- Trademark:Tongda

- Origin:China

- HS Code:8543300090

- Production Capacity:2 Sets,Month

Description

Basic Info.

Model NO. TD-B Machine Type Automatic Type/Semi Automatic Type Coating Zinc /Nickel/Copper/Chrome/Gold Coating Around Machine Filter/Chiller/Rectifier Manufacturer Yes Customized Yes After Sales Service Online Supports Service Longlife Technology Support Application on Nails, Bolts, Bullets etc Main Parts PP /PVC Tank.Crane Plating Style Barrel Type Electroplating Style Cool Plating Product Name Zinc Plating Machine Transport Package Plywood Box Specification Customized Trademark Tongda Origin China HS Code 8543300090 Production Capacity 2 Sets/MonthProduct Description

Automatic plating line electro zinc line barrel plating line/equipment price

Description of Semi Automatic Type Electroplating Machine

*High Productivity , stble quality ,saving time human and area.

* Intelligent operatin system controlled by PLC . Using the Man-Machine touched interface controlling panel , can monitor and adjust the every process and data.

* The Motor with reducer transmission to insure the barrel rolling

* The Most produce capacity can arrive 1-2 ton/hour

| Rank | Item | Automatic Electroplating Equipment |

| 1 | Material of tank | 15 mm PP(Polypropylenep) /PVC Plate (Polyvinyl chloride) and Customized |

| 2 | Material of framework | Galvanized Steel With Epoxy paint |

| 3 | Model | Automatic type |

| 4 | Control system | PLC System Control |

| 5 | Heating | Stainless Steel Heating Tube/Quartz Heating Tube/Titanium Heating Tube |

| 6 | Surrounding equipments | Rectifiers, Filters, Water Chiller ,Pipe, Air blower, waste gas treatment system and so on |

| 7 | Application | Different kind of plating for metal ,Steel and plastic products |

2.TanksMore detailed pictures of semi automatic electroplating machine:

1. Crane :

2. Barrels :

3. Frame Painted :

We use Epoxy paint to paint frame of machine , to keep frame from corrosion .

4.Machine itself :

5. Products :

Copper plating/Blue White zinc plating /Nickel plating etc

About us :

Junan Tongda Electronic Equipment Factory is one of the market leaders in electroplating industry. We have the honor to serve our customers , Our company is specialized in electroplating equipment and have many projects for these electroplating line. Along with the marketing demand and development our company .

With quick yet accurate response and handling, customer benefits are guaranteed.

Our factory is in Dadian Town ,Junan County , Linyi City , Shandong Province , China .

We are a manufacturer of Zinc/Chrome/Nickel/Gold/Silver/Aluminum Anodizing Equipments . No matter Automatic Type , Semi-Automatic Type , Manually Type , We could customized Equipment according to your requirements .

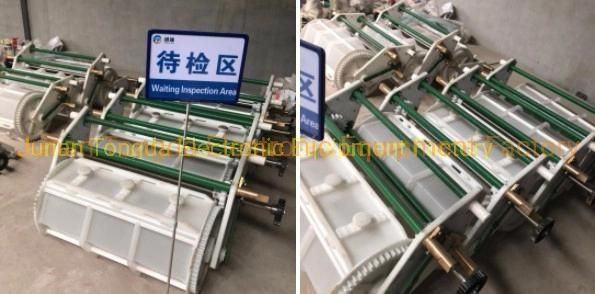

Before delivery:

Machine's Testing :

We will assemble all tanks , install lifting crane , and run the machine to test .

Then we could check all parts well , making sure that the machine could run well when our client receive the machine .

In addition, we will make a Loading List as well . On the one hand , our people could clear all items when they Load . On the other hand , it will be helpful for our clients to check and confirm all parts when they receive the machine .

Please kindly feel free to contact with us . We will do our best to help you.

Our advantages :

1. We use 15 mm PP (polypropylene)/PVC (polyvinyl chloride) to make tanks .

But actually , we also do survey on our market ,we found that most of suppliers used 10-12 mm PP plate to make tanks . We have the confident of our quality of tanks . It's more strong , and could use for a long time .

2. As manufacturer : We could give you a affordable price as well .

and provide lifelong technology supports , online supports etc.

And we warmly welcome you come our city to have a visit .

3. Free parts as gift

1 year warranty

Lifelong technology supports

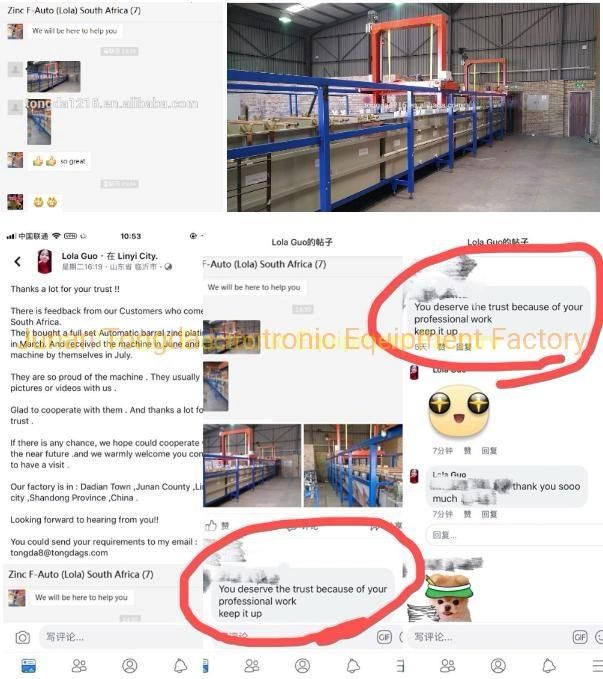

Customer's Feedback :

There is one client who comes from South Africa .

They ordered one full set Automatic Type Zinc plating machine in March , and got the machine in July . And they installed machine by themselves . They usually share pictures and videos with us in our groups . If there are any questions , we will try our best to help them solve it .

They are sooo proud of the machine .

Thanks for their trust !!!:P