500-3000mm Pipe End Facing and Beveling Machine for Spiral Welded Pipes

Taiyuan Huaye Equipment Research Institute (Co., Ltd.)- After-sales Service:Available

- Warranty:1 Year

- Automatic:Automatic

- Pipe O.D.:500-3000mm

- Length:6-12m

- Pipe Wall Thickness:6-32 mm

Base Info

- Pipe Weight:Max.42t

- Capacity:250 Kw

- Steel Pipe Weight:Max26t

- Steel Pipe Standard:API-5L

- Main Drive Motor:AC90kw*2

- Transport Package:Nude

- Trademark:HUAYE

- Origin:China

- Production Capacity:5-10sets,Year

Description

Basic Info.

Pipe Weight Max.42t Capacity 250 Kw Steel Pipe Weight Max26t Steel Pipe Standard API-5L Main Drive Motor AC90kw*2 Transport Package Nude Trademark HUAYE Origin China Production Capacity 5-10sets/YearProduct Description

Introduciton

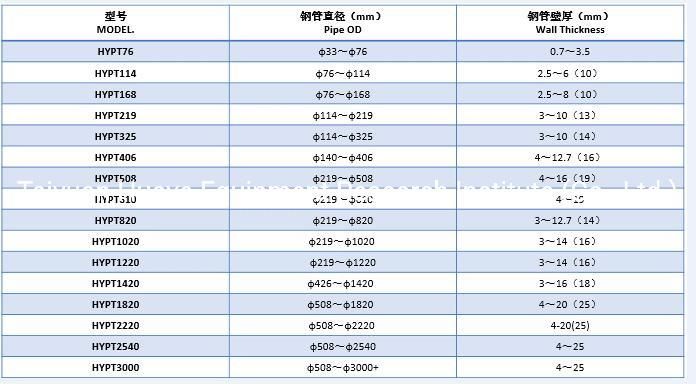

IntroducitonPipe end-facing and beveling machine is used for facing and beveling process on steel pipe ends. The beveling machine built by HUAYE covers the pipe size range of Φ50 - Φ3500mm.

The end facing and beveling fabrication are processed at the same time and finished in one cycle. Equipped with profiling rolls, the machine delivers satisfactory cutting quality.

End facing and beveling machine as one of HUAYE's major product, has been delivered over 100 sets since 1996. From simple design to high-level configuration, HUAYE provides most suitable selection for different customers.

Machine Features:

1. Unique structural design, make compact appearance and easy to operate.

2. The device is powerful, fast cutting, high efficiency.

3. New design machine clip cutter, accurate positioning fixture, and excellent hydraulic locking device to ensure the beveling quality.

4. Hydraulic system adopt Beijing HUADE hydraulic valve, effective control slide fast forward, working forward, return fast, safe and reliable operation.

5. Cutting equipment feed rate and cutting speed can be adjusted according to the size of the pipe diameter and wall thickness.

6. Low Investment,high return

Production Flow

Production FlowRack-Pipe installation -Pipe receiving -Pipe being lowered to carrying roller -Rotary conveyor rotates axially to move the steel pipe into the clamping device - Adjusting pipe to center-Clamping device locking-Quick feeding and tool feeding-Beveling &end facing-Box quick returning-Clamping device unlocking- Pipe being lowered to carrying roller-Rotary conveyor moves axially out of pipe-Pipe unloading-Next cycle