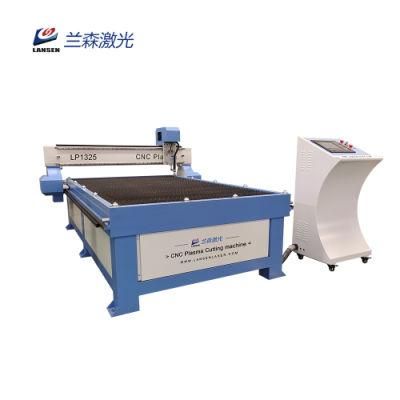

Metal Stainless Carbon Steel Powerful CNC Plasma Cutting Machines Cutter

Jinan Lansen Laser Equipment Co., Ltd.- After-sales Service:Online Service

- Warranty:2 Years

- Customized:Non-Customized

- Layout:Horizontal

- Cutting Material:Copper, Carbon Steel, Iron, Aluminum, Metal Alloy, Stainless Steel

- Automatic Grade:Semi-Automatic

Base Info

- Model NO.:LSP1325

- Power Source:Electric

- Cutting Mode:Plasma Cutting

- Working Material:Metal Steel, Stainless Steel, Carbon Steel, Alumin

- Motor Driver:Stepper Motor and Driver

- Control System:Start with USB Interface (Starfire Optional)

- Cooling Way:Water Pump and Water Tank

- Transport Package:Wooden Boxes

- Specification:1300kg

- Trademark:Lansen

- Origin:China

- HS Code:8465990000

Description

Basic Info.

Model NO. LSP1325 Power Source Electric Cutting Mode Plasma Cutting Working Material Metal Steel, Stainless Steel, Carbon Steel, Alumin Motor Driver Stepper Motor and Driver Control System Start with USB Interface (Starfire Optional) Cooling Way Water Pump and Water Tank Transport Package Wooden Boxes Specification 1300kg Trademark Lansen Origin China HS Code 8465990000Product Description

Metal stainless carbon steel powerful cnc plasma cutting machines cutter Features:

Features:- This machine adopts thick square tube wholly welding; the machine body adopts shaking preventing technical disposal, with the features of firm, shape retention, and high rigidity.

- Reasonable platform design, the flat table adopts 10mm precision process steel plate install on the machine table, and then install precision process cast iron cover to protect the vertical steel, to prevent the steel plate affected by high strength flame. The level difference of whole double-deck platform remains in 0-1.5mm.

- Reasonable pitch leaks design, to make the work piece and other fragments slide to the sides of the knife rack, safe and convenient to use.

- This machine adopts Starfire control system. StarCAM Software.

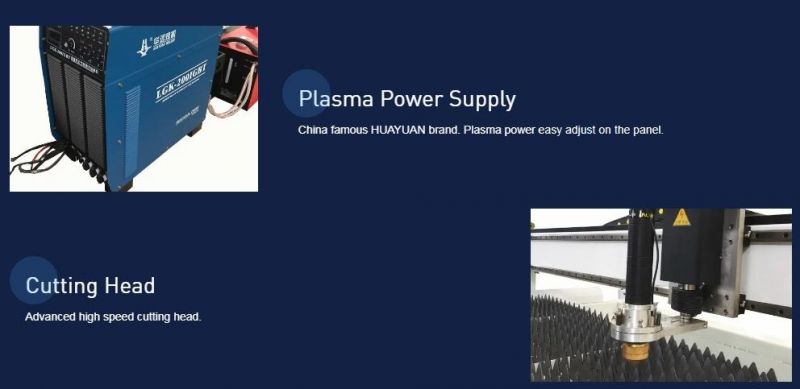

- The machine adopts Huayuan power source (power 63A/120A/200A) together with high sensitive arc pressure adjuster. Self-adjusting to choose the best distance between plasma head and work piece automatically in order to ensure cutting accuracy

- Perfect reasonable design and high immaculate surface's work piece make the machine best choice for different thickness material and heterotypic sheet cutting

Model | LSP1325 |

Working Area(X*Y) | 1300×2500mm |

Working Material | Metal steel, Stainless steel, carbon steel, aluminum,etc. |

Cut Material Thickness | 3-30mm |

Plasma Power | HUAYUAN 63A/100A/120A/160A/200A/300A (HYPERTHERM and Thermal Dynamics optional) |

Plasma Power Supply | 63A/100A/120A/160A/200A/300A |

X Y Z Rail | Taiwan PMI Square railway Linear guide |

Transmission | X/Y rack and pinion, Z Ball Screw |

Motor Driver | Stepper motor and driver |

Control System | START with USB interface (STARFIRE optional) |

Design software | FASTCAM (STARCAM,IBE optional) |

Command | G code, . PLT |

Working Mode | Untouched THC(torch height controller) |

Working Speed | 0-8000mm/min |

Plasma Cutting accuracy | +0.5mm |

Repeatability | 0.05mm |

Working Voltage | 380V,3PH,50/60HZ |

Table type | Sawtooth table |

Cooling way | Water pump and water tank |

Plywood package size | 3.61*2.28*1.61m |

Optional | Servo motor, water table, etc |

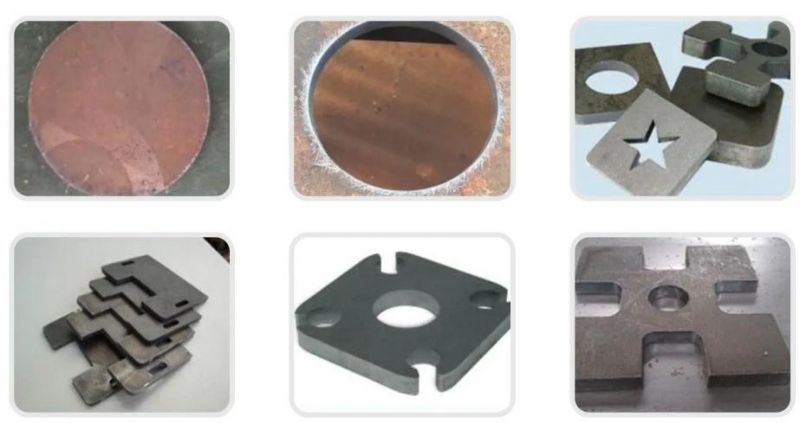

Application Materials:

Stainless steel, steel, iron,carbon steel, brass, copper, aluminum alloy, Titanium, etc

Application Industry:

Sheet metal, kitchenware, components, decorations industry, Ship Building,Construction Equipment,Transport Equipment,Aerospace Industry,Bridge Building,

Wind Power, Structural Steel, Boiler Containers, Agriculture Machinery, Chassis Electrical Cabinets, Elevator Manufacturers,Textile Machinery,etc.

Machine details:

Warranty:

1. 2 year for the whole machine.

2. 6 months for the Plasma generator.

3. Consumable parts are beyond the warranty lines.

4. etailed manual and video to guide the uses how to use the machine and maintenance supplied.

5. Technical support by website and phone.

6. If you meet the problems, we can solve it with pictures, videos ect

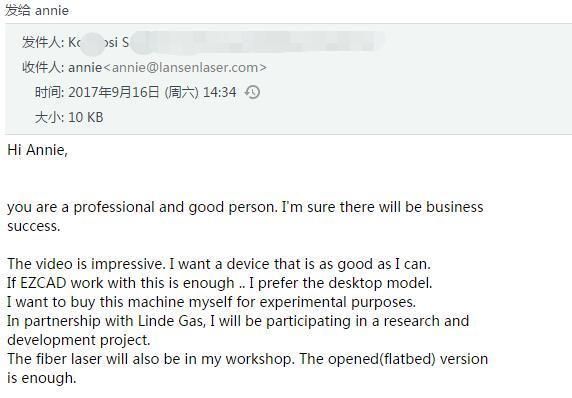

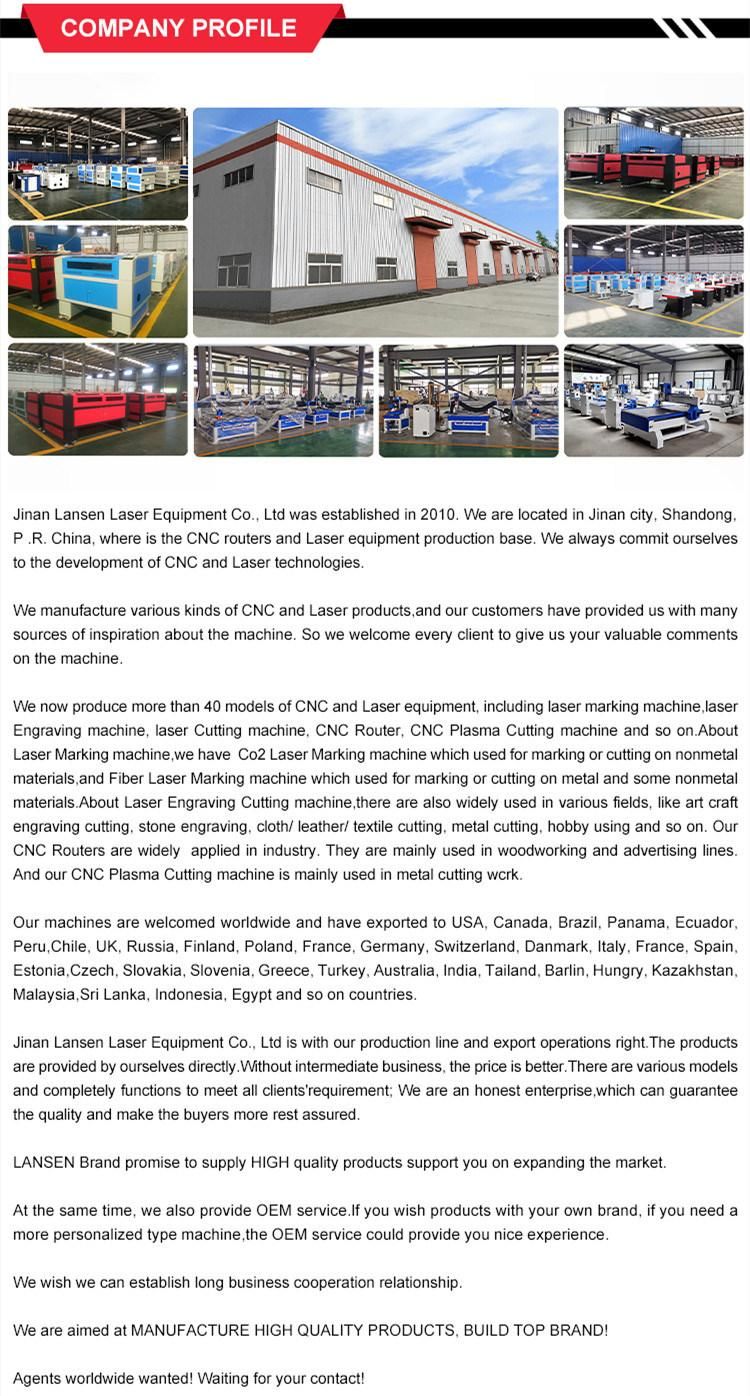

About us:

FAQ

Q: Are you a factory or trading company?

A: We are a manufacturer, we own our exporting rights.

Q: Where are you located? How can we visit you?

A: We locates in Jinan of Shandong, as long as you give us and email or telephone, tell us your visit plan, we will arrange all for you in Jinan.

Q: How can I choose suitable machine?

A: Please communicate with us via inquiry or email, we can guide you. Please kindly tell us:

1) .What work table size you will need?

2).What work you will do?

Q: What's your payment terms? Delivery time and MOQ?

A: We accept T/T(bank transfer), L/C, Paypal, ESCOW, West union etc. Usually we need 30%

as deposit, balance paid before shipment.

Delivery Time: 7-10 days after payment

MOQ: 1set

Q: If I bought a machine, how could you make it safe while shipping.

A: We have a professional package suitable for oversea transpotation. Machine will be fixed well in the case.

Q: What's your quality control system?

A: All machines will be tested after finished. We have QC department response for this job. And we already got CE approved.

Q: What's your after-sales service?

A: 1) Warranty 2 years for whole machine.

2) Engineers available service machinery overseas

3) Full operator training

Q: If I don't know how to use the machine, can you teach me?

A: 1) There is a DVD disc including machine user manual and software user manual c/w machine

2) Online (skype & phone)

3) Remote desktop software (Team viewer)

4) Demo Video

Q:This is my first time buy machine from China, how i buy machine from you?

A:Choose suitable machine through talking with our seller manager → Pay to us→ manufacture and testing machine (about 5-7 workdays) →shipping to you

More information, welcome to contact us!