OEM High Quality Flexible Jaw Sliding Coupling with CNC Machining

Weifang Shengao Machinery Co., Ltd.- After-sales Service:as Specification

- Warranty:6 Months

- Condition:New

- Certification:CE, ISO9001

- Standard:ASTM

- Customized:Customized

Base Info

- Model NO.:WF-JF

- Material:Metal

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

- Item:CNC Machining Coupling

- Raw Material:Stainless Steel, Carbon Steel, Aluminum, Brass

- Tolerance:+,-0.02mm

- Techincs:Machining

- Brand Name:Shengao,OEM

- Standard or Nonstandard:Nonstandard

- Factory:Over 15 Years Experience in Producing

- OEM:Available

- Dimension:10-100mm

- Certificates:SGS, ISO9001:2008

- OEM Service:Yes

- Csutom Made:Yes

- Logo Printing:Customized

- MOQ:100PCS

- Free Sample:Yes

- Transport Package:Pallet, Iron Frame, Flywood Box.

- Specification:SGS, ISO9001: 2008

- Trademark:ShengAo

- Origin:Weifang City, Shandong Province

- HS Code:7325109000

- Production Capacity:50000PCS,Month

Description

Features of jaw coupling:

Features of jaw coupling:

1.Easy of inspection,easy maintenance.

2.Can absorb vibration,parallel,angular and axial misalignments.

3.Identical clockwise and anticlockwise rotational charateristics.

4.Both ends material is iron, intermediate for rubber materials.

5.Simple configuration, setscrew type,low price.

6.Hole can be self-processing,easy facilitate.

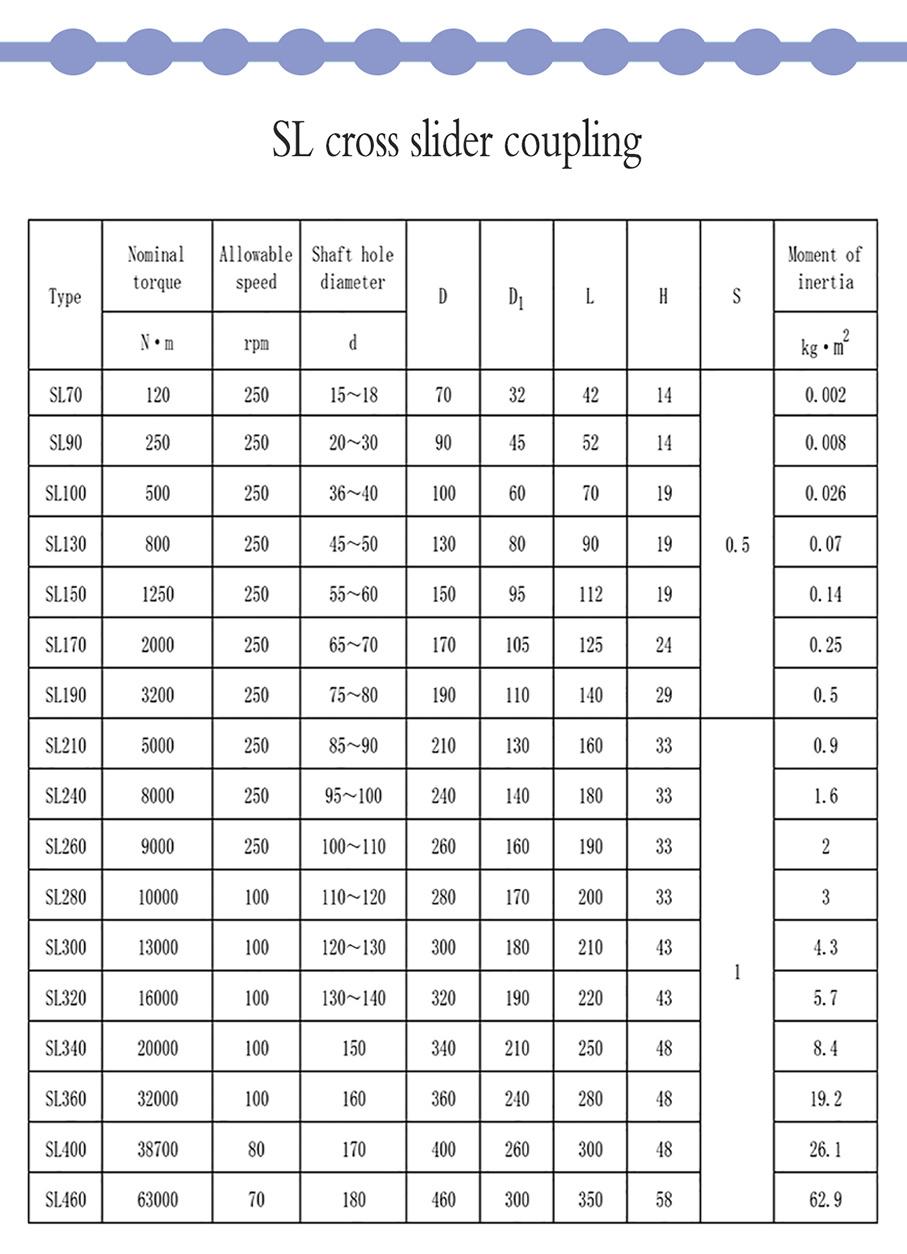

7.For step motor,screw, machine positioning system. The SL cross slide coupling is slid in the corresponding radial grooves of the large end faces

The SL cross slide coupling is slid in the corresponding radial grooves of the large end faces

of the half couplings on both sides.

The main feature of the slider coupling is that it allows the two shafts to have a large radial

displacement, and allows for small angular displacement and axial displacement. Due to the

centrifugal force generated by the eccentric motion of the slider, it is not suitable to use this

coupling. High-speed movement, the coupling torque of the coupling is 120-63000N.m, the

speed is 250-70r/min.

3D instruments, 2D instruments, Projectors, Height Gauges, Inner diameter dial indicators, Dial gaues, Thread

and Pin gauges, Digital calipers,Micro calipers, Thickness testers, Hardness testers Roughness testers, etc.

( Detection accuracy to 0.001 millimetre )

Advantages:

Protects driven component by serving as a mechanical "fuse" - an inexpensive replaceable plastic

midsection shears under excess load.

Protects support bearings by exerting consistently low reactive forces, even under large misalignments.

Homokinetic transmission - driving and driven shafts rotate at exactly the same speed at all times.

Zero backlash and high torsional stiffness.

Accommodates large radial misalignment in a short length.

Easy installation in blind or difficult installations when through-bores are used.

Economically priced compared to other couplings with similar performance characteristics.

CNC machining parts, metal machining parts, precision machining parts, Machined parts, Machinery

parts,Machine Parts,machining parts machining,Cnc machining parts machinery parts,machined

parts,precision machining parts,oem machining parts,cnc machining parts,cnc machined parts.

FAQ:

FAQ: 1. Are you a manufacturer?

Yes, all products showed in our website are produced in our factory

2. I want to keep our design in confidence; can we sign NDA?

Sure, to protect customers' profit is our obligatory responsibility, signed NDA would be valid to both of us..

3. What should I offer to get your quotation?

Please offer us your detailed information for the product, such as drawings with 2D/3D by software Pro/E, Auto CAD, SolidWorks, UG etc; as well as materials, surface treatment, quantity, package. Any special requirements should be highlighted especially for tolerance.

4.How long does it take to receive samples?

20 working days,the lead time is the general production period and does not include the transportation time.

we can supply free samples with less quantity,but customers need to pay shipping cost.

5.How long is the manufacturing lead time?

Mass Production:30-45 working days after sample approval by yours.The lead time is the general production period without the transportation time.

We could make some special production arrangement effectively if customer has urgent need.

6.How long does it take to ship goods from China by sea?

It takes about 5 weeks to European ports plus 1 week customs clearance, so you can get the container within 6 to 7 weeks.It takes about 2 weeks to east coast and 3 weeks to west coast US ports.All sea goods are shipped from Ningbo Port.

7.How long does it take to ship goods from China by air?

It takes about 7 days to all major destinations.

8.What are the payment terms?

Payment terms are negotiable and will improve for long term customers.During the initial stages, we request 50% of tooling fee in advance with the balance payable on acceptance of samples.Production orders can be negotiable.We prefer 30% deposit and the balance by T/T before sails.But sometimes T/T15 days after sails would also acceptable.

If there's anything we can help, please feel free to contact with us.