60b/80b/60d Automatic H-Beam Flange Hydraulic Straightening Steel Making Machine

Dongtai Yaoqiang Welding Facture Co., Ltd.- Type:Rotating Anti-Bending and Straightening Machine

- Usage:Sheet, H Beam Flange

- Voltage:220V

- Automatic Grade:Automatic

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:YJ-60B,80B,60D

- Customized:Customized

- Condition:New

- Feature:Simple Structure, Convenient Operation

- Correct Form:Mechanical ,Hydraulic

- Electrical System:Cabinet Control

- Weight:7000-28000kg

- Thickness of Flange:Less Than 80mm

- Equipment Structure Type:Stationary

- Advantage:Cheap and Effective

- Automatic or Not:Yes

- Customized or Not:Yes

- Color:Blue

- Transport Package:Wooden Package or Simple Package

- Specification:ISO

- Trademark:Yaoqiang

- Origin:China

- HS Code:8515800090

- Production Capacity:100 Pieces,Year

Description

ModelMechanical Hydraulic HYJ-600 HYJ-800 YJ-60B YJ-80B Thickness ≤ 20mm ≤ 40mm ≤ 60mm ≤ 80mm Tensile strength of flange ≤ 420Mpa ≤ 420Mpa ≤ 600Mpa ≤ 600Mpa Flange width 150-600mm 200-800mm 200-800mm 200-1000mm Web height ≥ 160mm ≥ 350mm ≥ 350mm ≥ 500mm Straightening speed 5.7m/min 17.0m/min 6.4m/min 6.0m/min Power of machine 9Kw 14Kw 37Kw 44Kw Weight 7000Kg 9000Kg 25000Kg 28000Kg

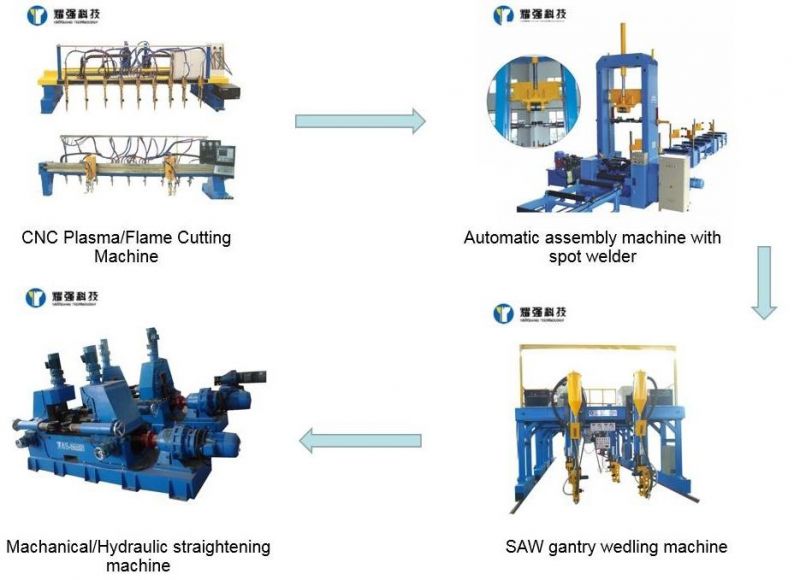

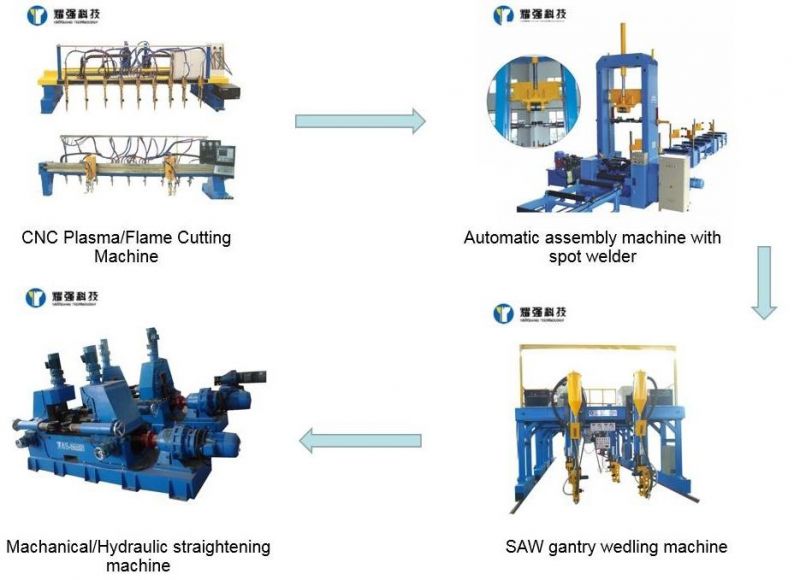

1. Equipment structure types: Stationary;

2. The correct form: Mechanical or hydraulic;

3. Equipment usage: Simple structure, convenient operation, capacity, correct speed, high degree of

Automatic;

4. Correction: High quality alloy wheel material after heat treatment, surface hardness and endurable

Wear-resisting performance;

5. Electrical system: The cabinet control.

3, Flange straightening machine:

After welding the T section steel or h beam, enter the correct location, using the working principle of hydraulic cylinder apical swing. Transmission efficiency is high, the straightening speed, all of straightening roller adopt a highquality alloy steel, and through the use of advanced heat treatment process, avoids the parts easy to generate crack defect, in order to ensure the correct stability and long service life and strengthen the treatment of all of its components are hosting with close control box operation, convenient operation.

4) scope of supply and component unit

Correction machines host including: Base, about the frame, motor, gear reducer, correction wheel, pressure roller, guide roller, etc.

Input/output roller bed including: Input/output roller bed each 2.6 * 4 meters.

Electronic assembly including: Electric cabinet, operation box and accessories.

Spare parts including: 1 set

5) technical documents

User manual (including electrical diagram, the vulnerability of figure, etc)

Shipping list

The certificate

FAQ:

Q1: I knew nothing about this machine, how am i know this machine will meet my working needs?

Please tell us your workpiece size or show specific drawings, we will give you professional solutions.

Q2: When I got this machine, but I don't know how to use it. What should I do?

We provide overseas service and English manual, after installation, if any problems happen, we offer the remote video guidance and charging overseas service.

Q3: If some problems happen to this machine during warranty period, what should I do?

Contact us directly, we will supply free parts during machine warranty period. While we also supply free life long after-sales service.

Q4: If i want visit your factory, how can i get?

Company address:39#, Liandong U business park, Wuxi city, Jiangsu, China

Factory address:Xinhong Industrial Park, Dongtai Yancheng City, Jiangsu, China

1), Visa: if u need get a government visa, pls pay 20%(at least) prepayment for new customer. Wuxi government regulations. Thanks for support.

2), By train: Wuxi station. By air: Wuxi Shuofang Airport. We will drive u to our factory. 180km between Wuxi and Yancheng city.

Q5: Why your sales office at Wuxi, but your factory located at Yancheng?

10 years ago. In response to the Yancheng government investment invitation, our leader moved the factory from Wuxi to Yancheng, purchased 15,000 square meters of land and built factories. In order to reduce production costs and sustainable development.

Tips: At present, the Jiangsu government is building the provincial high-speed railway. It is expected that Yancheng will open the subway in 2022.

Contact:

Website: http://yaoqiangwelding.en.made-in-china.com | http://yaoqiangwelding.en.made-in-china.com | http://yaoqiangwelding.en.made-in-china.com

Dongtai Yaoqiang Machinery Manufacture Co.,Ltd | Factory Addr.: Tangyang Town, Dongtai Yancheng city, Jiangsu, China

Jiangsu Silver Coast International Trade Development Co.,Ltd | Sales Office: #39 Liandong U Valley,Wuxi city,Jiangsu,China

1. Equipment structure types: Stationary;

2. The correct form: Mechanical or hydraulic;

3. Equipment usage: Simple structure, convenient operation, capacity, correct speed, high degree of

Automatic;

4. Correction: High quality alloy wheel material after heat treatment, surface hardness and endurable

Wear-resisting performance;

5. Electrical system: The cabinet control.

3, Flange straightening machine:

After welding the T section steel or h beam, enter the correct location, using the working principle of hydraulic cylinder apical swing. Transmission efficiency is high, the straightening speed, all of straightening roller adopt a highquality alloy steel, and through the use of advanced heat treatment process, avoids the parts easy to generate crack defect, in order to ensure the correct stability and long service life and strengthen the treatment of all of its components are hosting with close control box operation, convenient operation.

4) scope of supply and component unit

Correction machines host including: Base, about the frame, motor, gear reducer, correction wheel, pressure roller, guide roller, etc.

Input/output roller bed including: Input/output roller bed each 2.6 * 4 meters.

Electronic assembly including: Electric cabinet, operation box and accessories.

Spare parts including: 1 set

5) technical documents

User manual (including electrical diagram, the vulnerability of figure, etc)

Shipping list

The certificate

FAQ:

Q1: I knew nothing about this machine, how am i know this machine will meet my working needs?

Please tell us your workpiece size or show specific drawings, we will give you professional solutions.

Q2: When I got this machine, but I don't know how to use it. What should I do?

We provide overseas service and English manual, after installation, if any problems happen, we offer the remote video guidance and charging overseas service.

Q3: If some problems happen to this machine during warranty period, what should I do?

Contact us directly, we will supply free parts during machine warranty period. While we also supply free life long after-sales service.

Q4: If i want visit your factory, how can i get?

Company address:39#, Liandong U business park, Wuxi city, Jiangsu, China

Factory address:Xinhong Industrial Park, Dongtai Yancheng City, Jiangsu, China

1), Visa: if u need get a government visa, pls pay 20%(at least) prepayment for new customer. Wuxi government regulations. Thanks for support.

2), By train: Wuxi station. By air: Wuxi Shuofang Airport. We will drive u to our factory. 180km between Wuxi and Yancheng city.

Q5: Why your sales office at Wuxi, but your factory located at Yancheng?

10 years ago. In response to the Yancheng government investment invitation, our leader moved the factory from Wuxi to Yancheng, purchased 15,000 square meters of land and built factories. In order to reduce production costs and sustainable development.

Tips: At present, the Jiangsu government is building the provincial high-speed railway. It is expected that Yancheng will open the subway in 2022.

Contact:

Website: http://yaoqiangwelding.en.made-in-china.com | http://yaoqiangwelding.en.made-in-china.com | http://yaoqiangwelding.en.made-in-china.com

Dongtai Yaoqiang Machinery Manufacture Co.,Ltd | Factory Addr.: Tangyang Town, Dongtai Yancheng city, Jiangsu, China

Jiangsu Silver Coast International Trade Development Co.,Ltd | Sales Office: #39 Liandong U Valley,Wuxi city,Jiangsu,China