CNC Buffing Machine for Faucet Making

Fujian RBT Intelligent Equipment Co., Ltd.- After-sales Service:Technical Support, Online Support, Spare Parts

- Warranty:One Year

- Certification:ISO, CE

- Condition:New

- Voltage:380V

- Application:Metal Tube

Base Info

- Model NO.:RB-F6-QGJ-1009-Z07

- Applicable Industries:Bathroom Ware (Eg. Faucet), Hardware, Casting

- OEM:Machine Can Be Customized as Required

- Lead Time:15days

- Function:Surface Polishing, Grinding, Milling, Buffing

- Programming:Built-in Professional Polishing Program Module

- Total Power:35kw

- Max Size of Polishing Wheel:600mm

- Min Size of Polishing Wheel:400mm

- Number of Polishing Stations:4

- X Axis Travel:800mm

- Y Axis Travel:950mm

- Z Axis Travel:700mm

- Polishing Size Range:Diameter 500*500mm

- Transport Package:Export Safety Packing (Customized Packing)

- Specification:L5000*W2900*H3300mm

- Trademark:RBT

- Origin:Quanzhou, China

- HS Code:8460901000

- Production Capacity:200set,Month

Description

Basic Info.

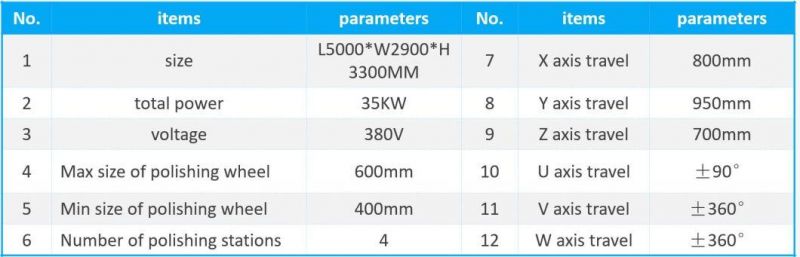

Model NO. RB-F6-QGJ-1009-Z07 Applicable Industries Bathroom Ware (Eg. Faucet), Hardware, Casting OEM Machine Can Be Customized as Required Lead Time 15days Function Surface Polishing, Grinding, Milling, Buffing Programming Built-in Professional Polishing Program Module Total Power 35kw Max Size of Polishing Wheel 600mm Min Size of Polishing Wheel 400mm Number of Polishing Stations 4 X Axis Travel 800mm Y Axis Travel 950mm Z Axis Travel 700mm Polishing Size Range Diameter 500*500mm Transport Package Export Safety Packing (Customized Packing) Specification L5000*W2900*H3300mm Trademark RBT Origin Quanzhou, China HS Code 8460901000 Production Capacity 200set/MonthProduct Description

CNC buffing machine for faucet making

Parameters

Machine Feature

1- This machine is a six-axis of four-station CNC cleaning machine with 6 degrees of freedom and four-station synchronous operation. It is widely used in product cleaning in the fields of sanitary ware, hardware, and auto parts;

2- Adopt advanced motion control system with stable performance and high control precision;

3-Programming method: use teach pendant programming of manual mode to simulate manual polishing and record the track, and run automatically according to this path

4- The clearing wheel is automatically compensated to effectively ensure the clearing accuracy;

5-Waxing setting: solid wax or liquid wax can be selected according to the characteristics of the product, and the waxing amount and frequency can be set freely;

6-Digital control, can store multiple programs and call them at any time

Application

PACKING & DELIVERY

1.Plastic film packaging and put in plywood wooden cases or according to customer's requirements.

2.Shipping : Container transport.

FAQ

Q1. Where is your factory located ? How can I visit it ?

A : Our factory is located in Quanzhou city,Fujian province,China. You can fly to Jinjiang or Xiamen air port, we will pick you up.

Q2. Are you produce polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings. Usually one machine have different molds and fixtures like metal polishing machine,die casting machine.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce or the spare parts.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: How is your development ability?

A: We have a strong engineer team to support the drawing, technology proposal, test and certification; We can customize the machine per customer requirement.

Q7: How about your after sales service?

A:We will arrange our technical staffs to your factory to install machine and teach you how to operate it. During the current special period, we will offer all support online via video 24h per day. Before shipment, we will test machine from and then send all videos from installation to production for customers. Full set of manual and instruction in English will be sent with machine together.