Cold/Coil/Steel Roll Cut to Length / Cut to Length Line Machine

Hangzhou Reliance Machinery Co., Ltd.- After-sales Service:Spare Parts Backup

- Type:Cold Rolled Steel Cut to Length Line

- Drive Mode:CNC

- Warranty:1 Year

- Line Speed:60-80m,Min

- Transport Package:Naked Packing with Fixing

Base Info

- Specification:3X1600

- Trademark:Reliance

- Origin:China

- Production Capacity:100 Set,Year

Description

Product Description

Detailed Photos

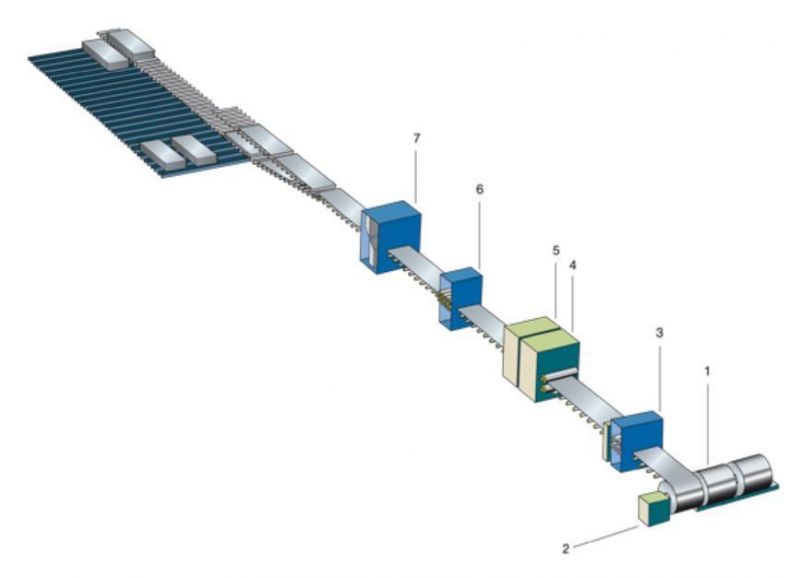

Working Process

Working ProcessThe steel sheet is fed into 4-hi precision leveler through guiding device, like traction head, peeler, pinch roll, and then sent to buffer pit through loop-bridge. By adjusting the correct device to centering of the sheet, it goes through into precision leveling & length measuring machine, and then the cutting machine to cut to length. The sheet is cut into required length controlled by PLC. The finished sheets are transported to auto stacker, and placed orderly.

Features

1. Using PLC system to control the whole line's work, the operation is convenient and easy.

2. Suitable material: stainless steel, cold rolled steel coil, etc.

3. The sheet coil is placed onto coil table by hoist/traveling crane, then loaded & elevated to appropriate position, and pushed into the spindle of decoiler by movement of trolley automatically.

Product Parameters

Our Advantages

FAQ

1. What's your warranty?

Two years, during which all parts damaged because of the quality problem will be changed for free, but not include damage caused by natural disaster or inappropriate operation or human factor.

2. What's your delivery time?

Within 60 days after receiving prepaid. Some machines are in stock, so can be delivered at any time.

3. What are your payment terms?

30% deposit is paid before production, the balance should be paid after inspection confirmation and before shipment.

4. What's your install and training?

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, a manual and video are provided to show how to install and operate.

5. What's your after-sale service?

We provide 24-hour online service for our customers.

(1) The seller will test the machines freely in China, and the traffic expense in

China of the technique people will be paid by the seller. When our engineer goes to the buyer's place to test the machines, the buyer should pay the expense of accommodation, and traffic for the buyer's engineer.

(2) If the buyer sends people to receive the training of the operation given by the seller, during the training period, the seller should pay the expense of accommodation, and traffic for the buyer's engineer, as well as daily salary of USD 150.

6. How to place an order?

Inquiry---Confirm the profile drawings and price----confirm the PI---Arrange the deposit or L/C---Start design and production--- Test and inspection --- Pay the balance --- Arrange shipping