Double Layer Glazed Corrugated Roof Tile Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- After-sales Service:1

- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Certification:CCC, ISO9001, CE

Base Info

- Model NO.:850

- Warranty:12 Months

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Name:Double Layer Sheet Metal Forming Machinery

- Equipment Operation:Automatically

- Voltage:380V, 50,60Hz or at Buyer′s Request

- Thickness of Material Sheet:0.3----0.8mm(Normally)

- Width of Material Sheet:914,1000,1200,1220,1250mm

- Control System:by PLC(Imported Brand)

- Cutting Method:Hydraulic Cutting

- Material of Roller Station:45# Steel with Hard Chromed

- Working Speed:10---12m,Min

- Transmission Type:Chains and Gears

- Transport Package:Water-Proof Packaging, Covered with Plastic Film

- Specification:DX 840,850

- Trademark:DIXIN

- Origin:Botou Hebei China

- HS Code:845522

- Production Capacity:20 Set Per Year

Description

Basic Info.

Model NO. 850 Warranty 12 Months Customized Customized Advantage Use Widely Condition New Name Double Layer Sheet Metal Forming Machinery Equipment Operation Automatically Voltage 380V, 50/60Hz or at Buyer′s Request Thickness of Material Sheet 0.3----0.8mm(Normally) Width of Material Sheet 914/1000/1200/1220/1250mm Control System by PLC(Imported Brand) Cutting Method Hydraulic Cutting Material of Roller Station 45# Steel with Hard Chromed Working Speed 10---12m/Min Transmission Type Chains and Gears Transport Package Water-Proof Packaging, Covered with Plastic Film Specification DX 840/850 Trademark DIXIN Origin Botou Hebei China HS Code 845522 Production Capacity 20 Set Per YearProduct Description

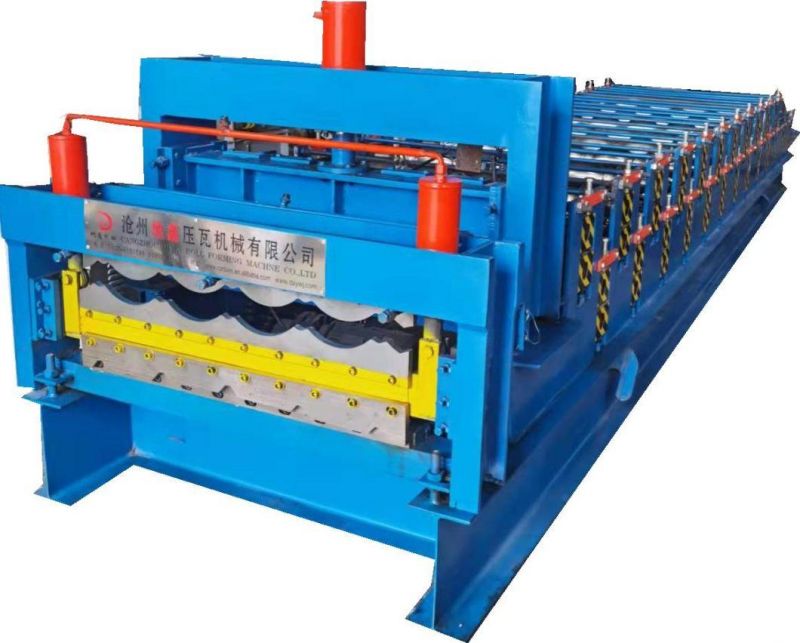

Double Layer Sheet Metal forming machineryThis machine is perfectly combined two different model machines together, this can save the space and also

Is easy to operate. The two models are chose according to customers' need.

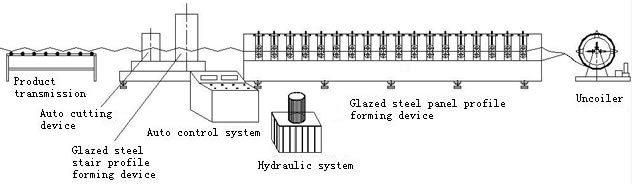

It consists of feeding platform, main molding machine, shearing mechanism, hydraulic station, computer control

Cabinet, high precision counter and so on.

1.Machine working flow:

Manual Uncoiler---Feeding Platform---Main Roll Forming---Measuring Length---Computer Control Box---Hydraulic Station---Auto Hydraulic Cutting---Products Receiving Table

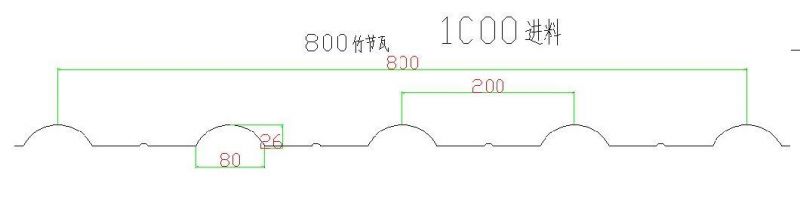

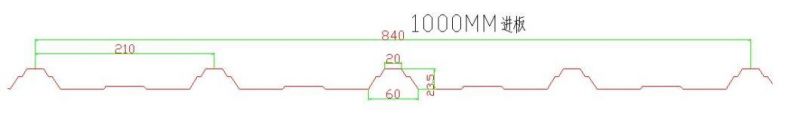

2.Panel drawing as customers request

3.Double deck coloful steel roller forming machine

(1) Suitable material: Galvanized sheet/ aluminum

(2) Thickness of the plate: 0.3mm-0.8mm

(3) Input width: 1000mm

(4) Effective width: 800mm/840mm

(5) Productivity: 8-12m/min

(6) Roller steps: 13rows

(7) Roller material: 45# steel Rolling chromium thickness: 0.05 mm

(8) Diameter of active shaft: 75mm

(9) Wall thickness of the main forming machine: 16mm steel plate

(10)Main forming machine body: 350mmH steel

(11) Transmission chain is1.0''

Reducer is 5.5kw Xingxing Cycloid which works stably and no noise

(12) Cutting hydraulic system adopts CDF-10 gear pump, the motor power is 4kw, no noise, work stably, long life expectancy.

(13) Taida PLC control system, easy to operate, high precision and work stably.

(14) Dimensions of major structure: 8500mm*1500mm*1600mm

4.Note: The measurement is an approximation and that in reality there may be a slight difference

5.Consist of

1 uncoiler and its base,

2 coil sheet guiding equipment

3 coll forming system

4 post cutting equipment

5 hydraulic station

6 controlling system

7 supporter table.

6.Company Introduce:

Our enterprise, Cangzhou Dixin Roll Forming Machine Co., Ltd, as the professional and leading manufacturer, can manufacture, design, installation and debug various roll forming machines and metal processing sheet equipments, which produce metal roof wall panel, glazed roof tile, CZ steel purlin, floor decking, roof ridge cap, sandwich panel, roof truss, shutter panel, shutter slat, door frame, guardrail, and metal sheet uncoiler, bending, slitting, cutting, flattening, punching, crimping.

Backed by reasonable design, precision machining and selected material, both our standard and customized machines are characterized by long life span, precise forming and easy operation. With our customers' trust, our machines have been sent to America, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil, etc.

Warmly welcome to China to visit our factory and select the machines you need. Our address, Fuzhuang Industrial Development Zone, Botou City, Hebei Province, China

.Packaging Details:

Nude,with waterproof cloth and stow-wood. Imported computer control system packed with waterproof cloth and card board.

2.Port:TIANJIN XINGANG PortLead .

3.Time: Shipped in 35 days after payment.

Usually the welding pipe cold roll forming machine can be packed into one 20' feet container or 40' feet container. We have good relationship with the shipping agent. Either you can find the shipping line at your side or we can help you.

FQA

Q: Are you manufacturer?

A: Yes, we are manufacturer and trading company.

Q: What kind of payment term you can do?

A: We are flexible about payment terms, please contact us for details.

Q: What info you need before you make the proposal for a roll forming machine?

A: The profile drawings, material informations, your special requirements.

Q: What's your service ?

A: 1. We provide 1 year warranty for our customers.

2. Any parts damaged because of quality problem will be changed for free within the first year.

3. Technical support is provided for free in the whole life of the machine.

30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 30-45 days for delivery.

If you want to get more information about our equipment ,