Steel Aluminum Casting Part Furniture Hardware Door Knob Handle

Kunshan JST Industry Co., Ltd.- Condition:New

- Certification:CE, RoHS, GS, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

- Material:Stainless Steel, Aluminum,Carbon Steel, Brass,etc.

- Application:Metal forging Machinery, Metal Casting Machinery

Base Info

- Model NO.:Casting (JST-C008W)

- Name:Furniture Handle

- Processing Method:Casting,Machining

- Roughness:Ra0.8

- Finish Treatment:High Polishing

- Applied:Cabinet ,Kitchen,Furniture

- Sampling Time:15-20days

- Transport Package:1 PC in a PE Bag, 20 Kgs Each Carton.

- Specification:Non-standard, Customized.

- Trademark:JST or OEM

- Origin:Jiangsu, China

- Production Capacity:80, 000 PCS , Month

Description

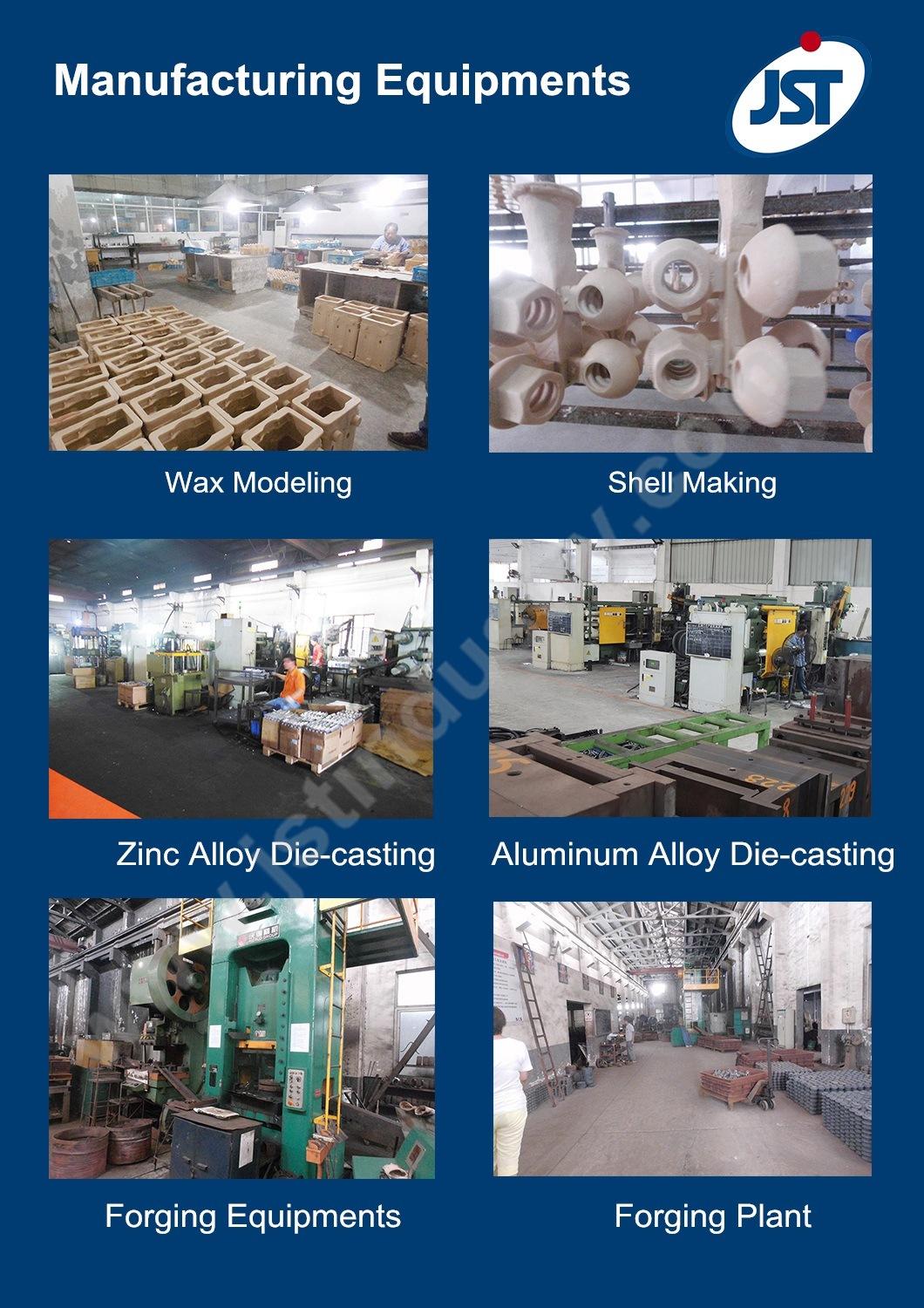

Casting is the most important sector in JST Industry, we have been a trusted manufacturing supplier in this field for over 15 years. We have built an impeccable reputation on quality, customer service and utilizing state-of-the-art equipment. Our expertise has made us the Best in Quality and Innovation.

Based on our manufacturing facilities and the local co-operating factories, we could do the sand castings, investment castings (lost wax castings), aluminum alloy die casting, zinc alloy die-castings and forgings. We could also do the additional machining for these parts, and also the finish treatment (heat treatment, sand blasting & anodizing, polishing, powder coating, etc..) as well.

Other Machining Facilities

Other assist equipments include:

Milling machine, Drilling machine, Centerless Grinding machine, External Cylindrical Grinding machine, etc.

Inspection equipment:

Vernier Caliper, Micrometer, Height Gage, Hardness Tester, Two-dimensional image measuring instrument, Mitutoyo surface Roughness Tester, Mitutoyo CMM and Ultrasonic Cleaner.

FAQ

Q1: Are you a trading company or a manufacturer?

Manufacturer.

Q2: How long is your delivery time?

Normally, the samples delivery is 10-15 days and the lead time for the official order is 30-45 days.

Q3: How long will it take to quote the RFQs?

Normally, it will take 2-3 days.

Q4: Do you provide samples?

Yes, the samples will be free if the cost is not too high.

Q5: Which countries are your target markets?

America, Canada, Europe, Australia and New Zealand.

Q6: Do you have experience of doing business with overseas customers?

Yes, we have over 10 years exporting experience and 95% of our products were exported to overseas market. We specialized in the high quality OEM parts, we are familiar with the standard of ANSI, DIN, ISO, BS, JIS, etc..

Q7: Do you have reference customers?Yes, we have been appointed as the supplier of Parker(USA) since 2012. "Supply the top quality precision machined parts" is our management philosophy,

ON TIME and EVERYTIME