OEM CNC Machined Steel Piston Guide Sleeves with Customized Machining Service

Weifang Shengao Machinery Co., Ltd.- Warranty:6 Months

- Condition:New

Base Info

- Model NO.:WF_JF

- Certification:CE, RoHS, GS, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

- Material:Metal

- Application:Metal Processing Machinery Parts

- Item:CNC Machining Part

- Supply:Drawing Design

- Quality Control:100% Inspected

- Shape:All Kinds of CNC Machining Parts

- Advantages:Delivery on Time, According to The Demand for Mat

- Delivery:Within 20 Days After Receiving Last Confirm Inform

- Machining:CNC

- Brand Name:Customized

- Shipping Port:Qingdao Port

- Business Type:Factory

- OEM Service:Yes

- Custom Made:Yes

- Logo Printing:Customized

- MOQ:10-1000PCS

- Free Sample:Yes

- Transport Package:Plywood Box

- Specification:SGS, ISO9001: 2008, ASTM, GB, DIN, EN124

- Trademark:Shengao

- Origin:Weifang City, Shandong Province, China

- HS Code:87089910

- Production Capacity:50000PCS,Month

- Package size per unit product:50.00cm * 20.00cm * 20.00cm

- Gross weight per unit product:5.000kg

Description

Basic Info.

Model NO. WF_JF Certification CE, RoHS, GS, ISO9001 Standard DIN, ASTM, GOST, GB, JIS, ANSI, BS Customized Customized Material Metal Application Metal Processing Machinery Parts Item CNC Machining Part Supply Drawing Design Quality Control 100% Inspected Shape All Kinds of CNC Machining Parts Advantages Delivery on Time, According to The Demand for Mat Delivery Within 20 Days After Receiving Last Confirm Inform Machining CNC Brand Name Customized Shipping Port Qingdao Port Business Type Factory OEM Service Yes Custom Made Yes Logo Printing Customized MOQ 10-1000PCS Free Sample Yes Transport Package Plywood Box Specification SGS, ISO9001: 2008, ASTM, GB, DIN, EN124 Trademark Shengao Origin Weifang City, Shandong Province, China HS Code 87089910 Production Capacity 50000PCS/MonthPackaging & Delivery

Package size per unit product 50.00cm * 20.00cm * 20.00cm Gross weight per unit product 5.000kgProduct Description

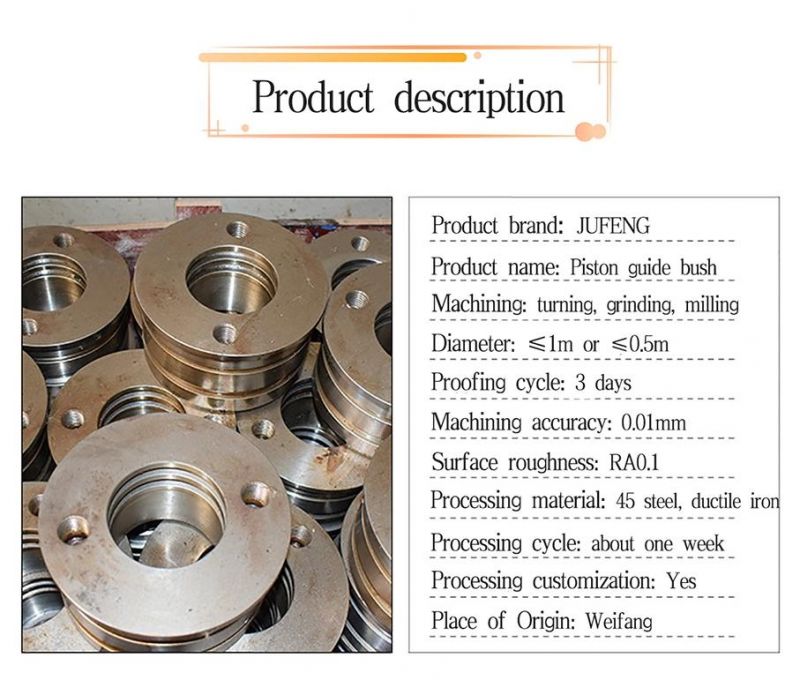

OEM CNC Machined Steel Piston Guide Sleeves with Customized Manufacturing Service

We are manufacturer of Machining Product, Screw Product, Turning Part. We are capability in manufacture no standard metal machining / turning product according to customer's drawing / samples and requirement. The material can be normal steel, Iron, SUS304, 301, 303, Brass, Copper, etc.

We also providing our customers with remarkable OEM solutions to meet your requirements. We believe our product quality and price will be able to enlarge your competitive price in your market. Small order is acceptable, OEM requirement is ok.

Specification

Material: Stainless Steel: 303 / 304 / 316(L) / 410 etc.

Dimension: According to the drawing or samples

Processing Equipment : CNC machining center, CNC turning, Grinding machine, CNC Milling machine, Drilling machine etc.

Surface treatment: Polishing, Plating, Anodized, Heat treatment, Inactivation, powder coating etc.

Packing: PE bag, Carton, Wooden box

Samples:Available in 7-20 days for different items

Inspection equipment: CMM (Coordinate measuring machine), Projector, Caliper, Micrometer, Roughness tester, Hardness gauges etc.

Service Items:Product design, production, technical support and after-sales service, mould processing and development etc.

Service: Warm and quick response provided by professional sales team with many years` experience of handling exportation to the US, Europe, Japan and other countries and regions

Advantages:

1. Over 7 years factory experience

2. High quality control, Competitive price, Fast delivery

3. Small quantity acceptable

4. Sample and drawing available

5. OEM workable

6. One-stop service

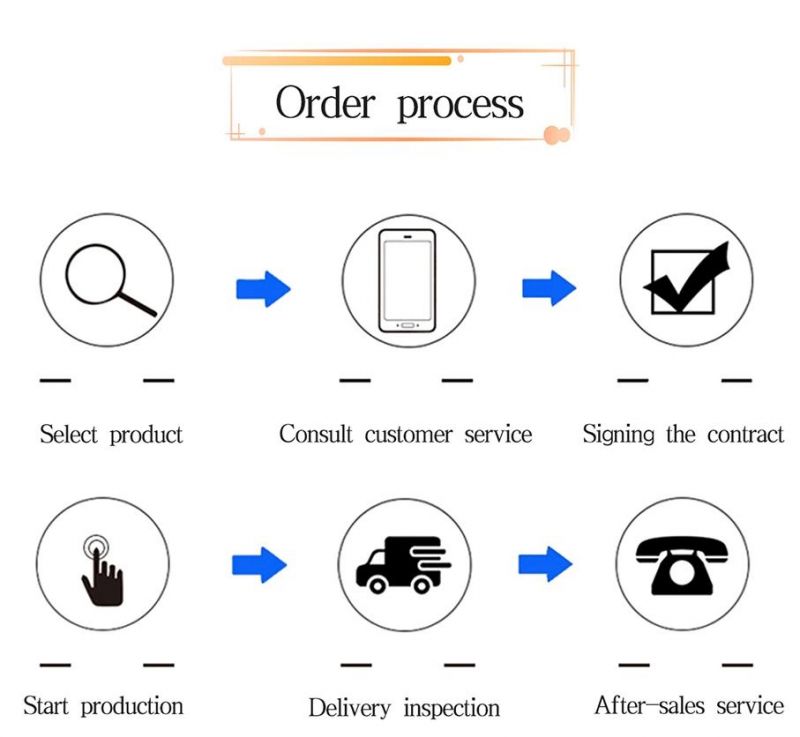

How to order:

How to order:

* You send us drawing or sample

* We carry through project assessment

* We give you a design

* You think the design is ok

* We make the sample and send it to you

* You think the sample is good then place an order and pay us 30% deposit

* We start to make the product

Inspection Equipment:In order to ensure the quality of the orders,our independent QC members to carry out strict inspection at each stage:

1. Raw material: supplier audit & incoming material AQL sampling check;

2. In-process: AQL sampling inspection special for critical dimensions;

3.100% inspection before packing;

(3D instruments, 2D instruments, Projectors, Height Gauges, Inner diameter dial indicators, Dial gaues, Thread and Pin gauges, Digital calipers,Micro calipers, Thickness testers, Hardness testers Roughness testers, etc. Detection accuracy to 0.001 millimetre )

4. QA AQL sampling inspection for Finishing products.

Material Available:

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |