Robotic Arm Spraying Powder Coating Euqipment

Hebei Hanna Technology Co., Ltd.- Type:Coating Production Line

- Coating:Powder Coating

- Substrate:Steel

- Certification:CE, ISO, RoHS, REACH

- Condition:New

- Feature:High Automatic

Base Info

- Model NO.:HN-PC01

- Color:as Request

- Transport Package:Choose According to Customer Needs

- Specification:customized

- Trademark:HANNA

- Origin:China

- HS Code:8424300000

- Production Capacity:20 Sets, Year

Description

Basic Info.

Model NO. HN-PC01 Color as Request Transport Package Choose According to Customer Needs Specification customized Trademark HANNA Origin China HS Code 8424300000 Production Capacity 20 Sets/ YearProduct Description

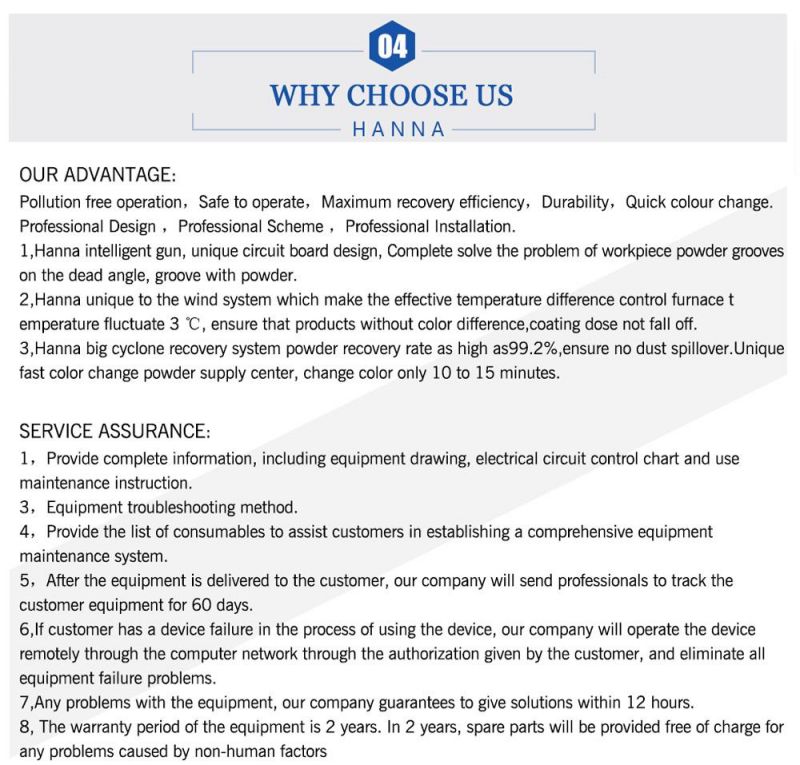

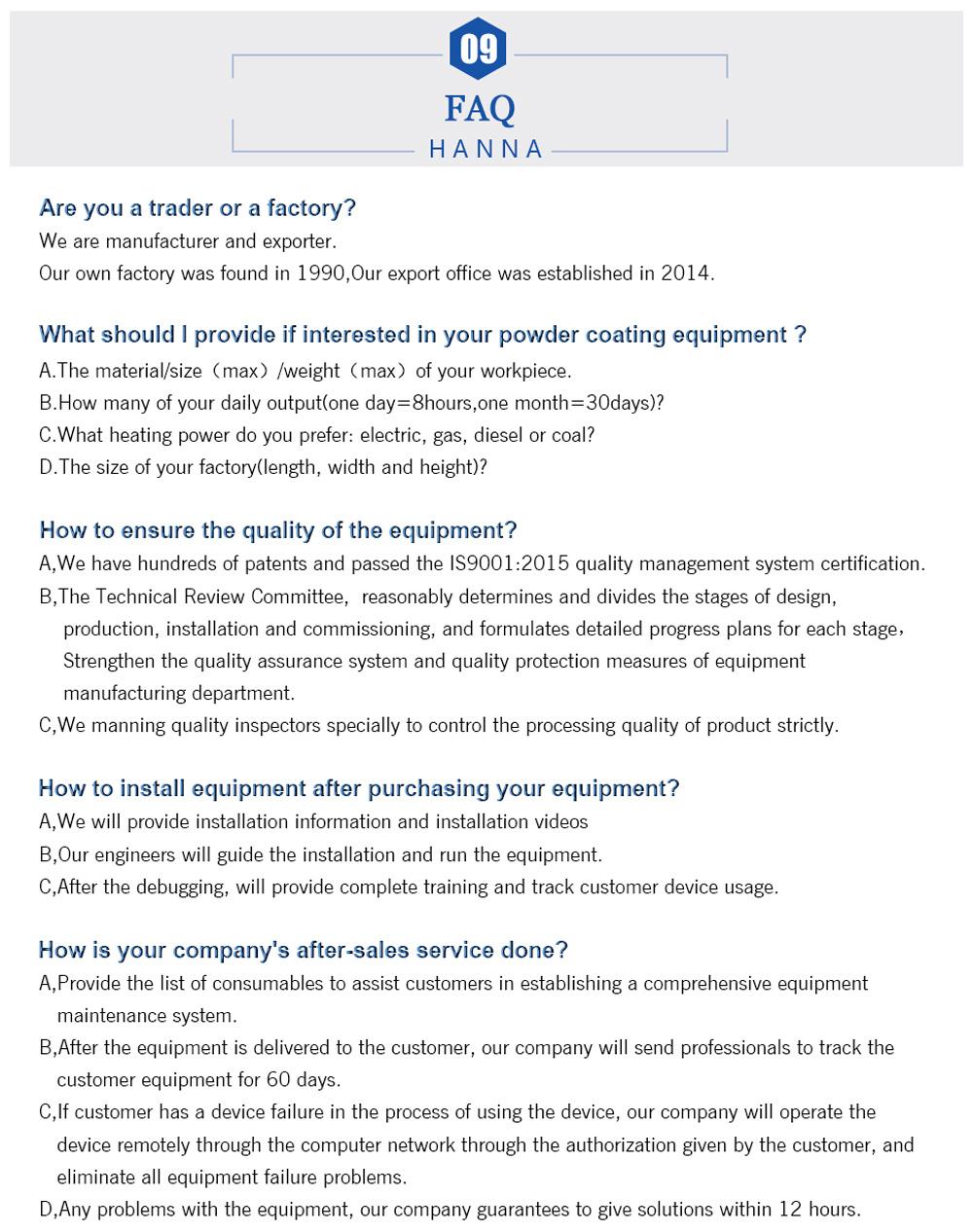

Our factory successfully developed a double line design of the full automatic powder coating production line - Power And Free Overhead Conveyor, which effectively improves work efficiency, saves raw materials, and occupy less area than the other powder coating production line, solves the problem of the small size of the factory.

The power and free overhead conveyor line is also called the power and free conveyor. The power and free overhead conveyor line can transport and temporarily store workpieces on the conveyor line, prevent the workpiece from continuing to be transported and adjust the spacing or the rate of workpieces. The items to be transported should not be too small. Gravity roller wheel and rollers are the cheapest and simplest storage conveyors commonly used.

Features:

1.The production capacity doubled for same time,

2. Energy consumption cost reduce by half

3. Occupy area reduce by half

4.Choose a special suspension conveyor chain, accumulation chain or ground chain that is specially adapted to the production environment

5. The position of the drive and tensioning device is chosen reasonably, through point-by-point tension calculation

6. Drives or multiple drives are synchronized using a frequency converter and closed-loop synchronous control circuitry

7. No creeping and jittering of the entire suspension conveyor system

hanan powder coating equipment customize

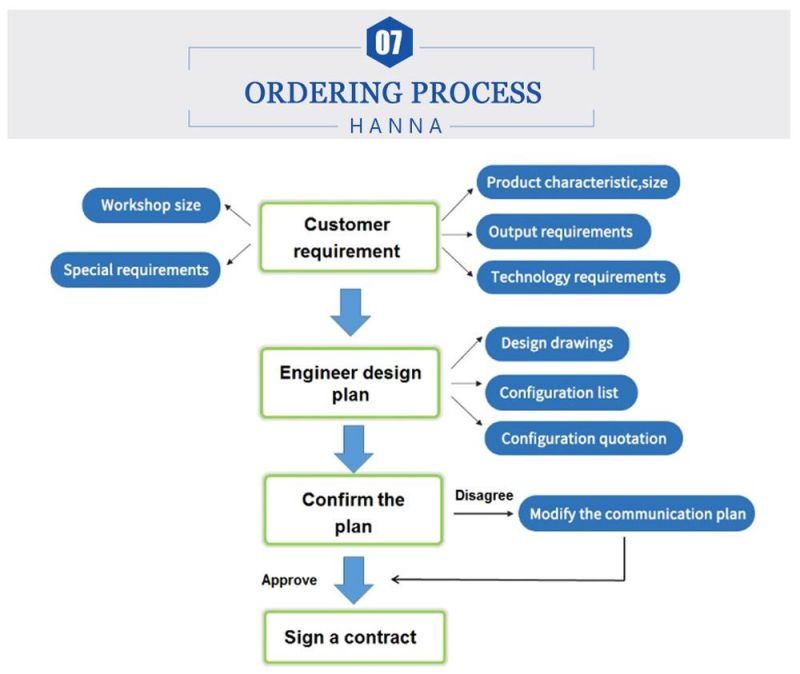

If you want to custom made aluminium alloy powder coating line,pls tell us the following specifications:

1.The size of your workpiece .

2.The output of your workpiece(one day=8hours,one month=30days).

3.How many colors do you need to spray?

4.The heating power you prefer:electric,gas,diesel,or coal.

5.The size of your factory(length,width and height).

We could make the design according customer's requirements.Pls contact with me and we will give you the quick reply.

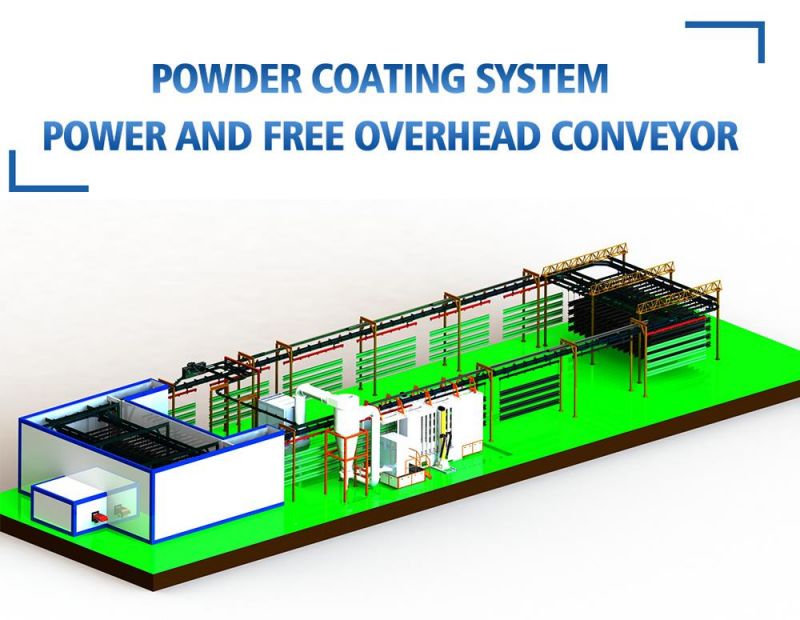

| Equipment | Application |

| Pre-treatment System | Better powder coating of the work-piece. |

| Powder Coating Room | Spraying on the surface of the work-piece. |

| Big Cyclone | Automatic fast color change. |

| Transport System | Delivery of work-pieces. |

| Curing Oven | It makes the powder attaching to the work-piece. |

| Heating System | The fuel can choose diesel oil,gas,electric etc. |

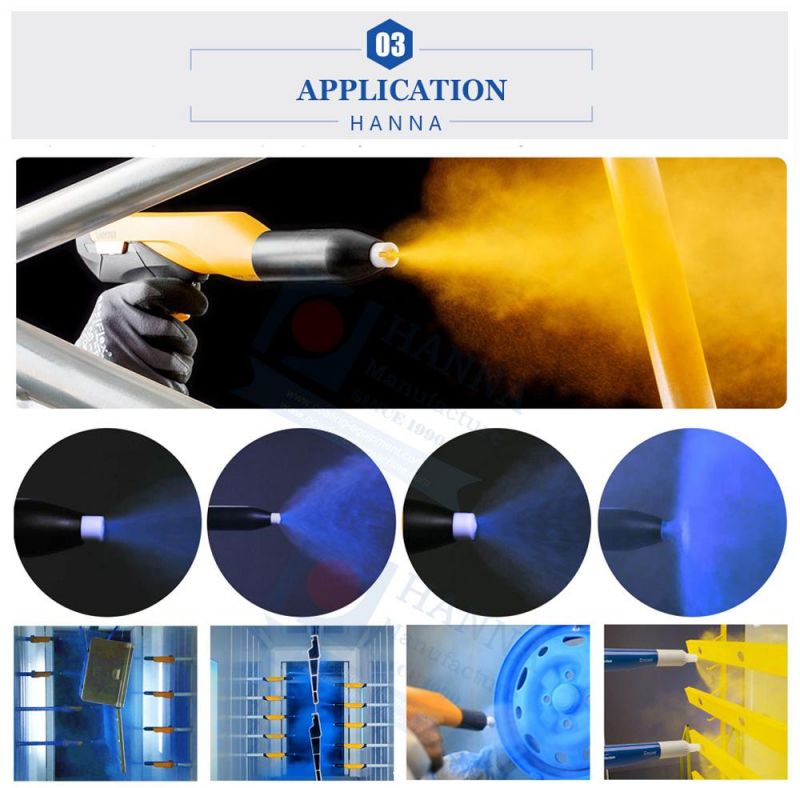

All the powder coating equipment and paint spraying equipment are widely used in all metal workpieces,

transportation industry, hardware industry, building materials decoration, security, home appliances,

mechanical engineering, wire mesh, electrical appliances, instrumentation, radiators, security doors,

pipes, valves, furniture, shelves, hangers, lamps, fire extinguishers and many other fields.