Automatic Guarding Fence Wire Mesh Net Welding Machine

Hebei Jiake Welding Equipment Co., Ltd.- Type:Welded Wire Mesh Machine

- Voltage:220,380,415,440V

Base Info

- Model NO.:JK-FS-2500A

- Style:Customized

- Warranty:1 Year

- Wire Diameter:2.5-6mm

- Mesh Opening Size:50*25-300*300mm

- Mesh Width:Max.2.5m

- Mesh Length:6m

- Control System:Panasonic PLC

- Raw Material:Ribbed Bar&Round Bar

- Welding Speed:45-75times,Min

- Power Supply:120kw

- Machine Name:Steel Reinforced Welded Wire Mesh Fence Machine

- Transport Package:Plastic &Wooden Box

- Specification:CE, SGS, ISO

- Trademark:JIAKE

- Origin:Anping, Hebei, China

- HS Code:8463300000

- Production Capacity:4500kg

- Package size per unit product:840.00cm * 320.00cm * 170.00cm

- Gross weight per unit product:4500.000kg

Description

1. The bracket and auxiliary equipments will be with plastic package, spare parts in carton box.

2. The main machine will be fixed in the container by steel wire

Application: railway, highway, Bridges, buildings, such as residential fence and shelves, warehouse cage welding

Material: low carbon wire, galvanized wire.

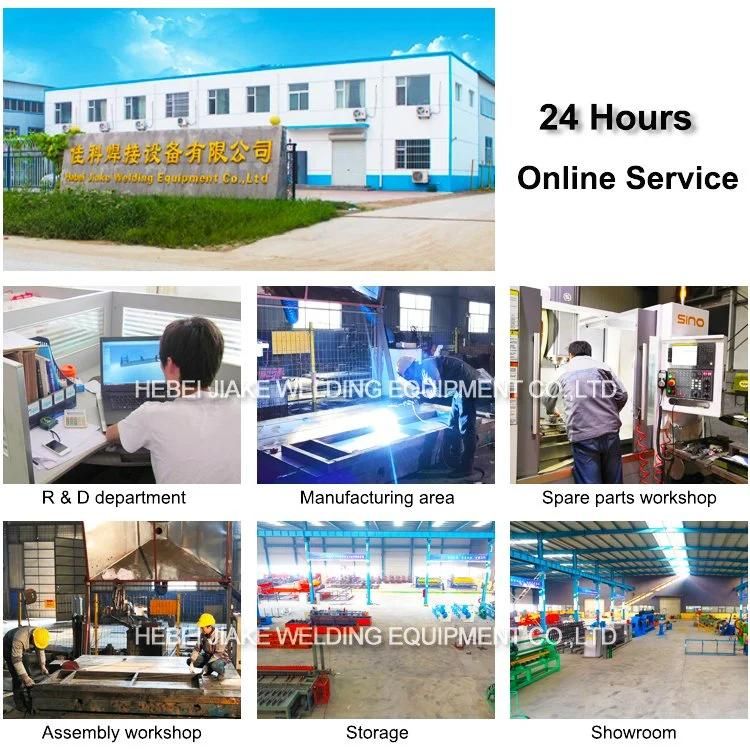

Best After-sales Service

1. Guarantee time: one year since machine was at buyer's factory but within 18 months against B/L date.

2. Within guarantee time, if any components are broken under normal condition, we can change for free.

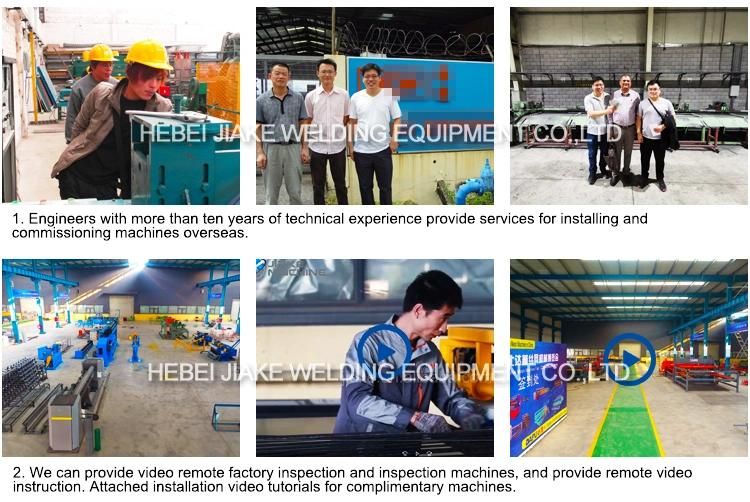

3. We can send our best technician to buyer's factory for installation, debugging and training.

4. Complete installation instructions, circuit diagram, manual operations and machine layout.

5. Timely reply for your machine questions.