Zinc Ash Separator of Hot DIP Galvanizing Line Zinc Ash Recovery Machine

Hebei Annuo Automation Technology Co., Ltd.- After-sales Service:Yes

- Warranty:12 Months

- Type:Coating Production Line

- Coating:Galvanized

- Substrate:Steel

- Certification:CE, ISO, SGS

Base Info

- Model NO.:Zinc Ash Separator

- Condition:New

- Operation Mode:Automatic, Semi Automatic, Manual

- Installation:Concluded as Customer Required

- Annual Output:Customized as Per Requirement

- Transport Package:as Required

- Specification:Customized

- Trademark:ANNUO

- Origin:Hebei China

- HS Code:8543300090

- Production Capacity:15000 Sets, Years

Description

Basic Info.

Model NO. Zinc Ash Separator Condition New Operation Mode Automatic, Semi Automatic, Manual Installation Concluded as Customer Required Annual Output Customized as Per Requirement Transport Package as Required Specification Customized Trademark ANNUO Origin Hebei China HS Code 8543300090 Production Capacity 15000 Sets/ YearsProduct Description

Zinc Ash Separator of Hot Dip Galvanizing Line

Hot Melt Type Zinc Ash Recovery Furnace is a kind of equipment which is used to recycle free zinc from zinc ash in hot dip galvanizing plant. It can recycle above 95% of free zinc particles from zinc ash and the recycled zinc can be directly added into zinc kettle. The rest of the zinc oxide ash can be sold to zinc chemical companies. According to different content of free zinc in zinc ash, 300-700kg zinc will be generally separated from 1000kg zinc ash.

Working temperature:536ºC

Zinc Kettle:

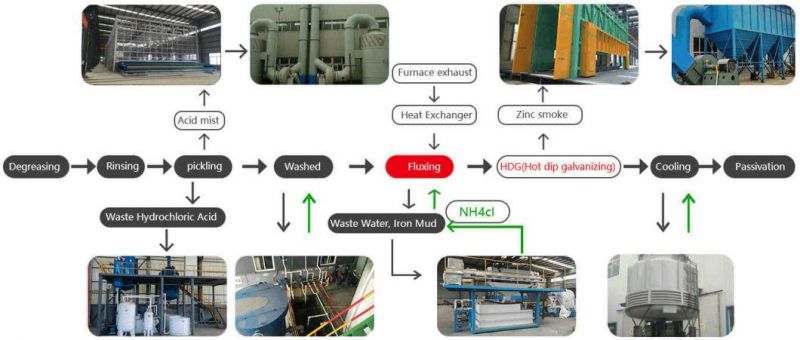

The Technical Process of Whole Galvanizing Line

Our Advantages:

- Technical advantages

Strong research team including 50 experts, professors, senior engineers and other high-tech R&D specialists.

Established strategic partnership with famous universities and research institues in China and abroad.

World-Class leading hot-dip galvanizing techniques.

Latest concept of factory and production line design.

Capability of new equipment invention and development.

- Planning and design advantages of whole production line

- Quality advantages

- Project construction advantages

- Service advantages