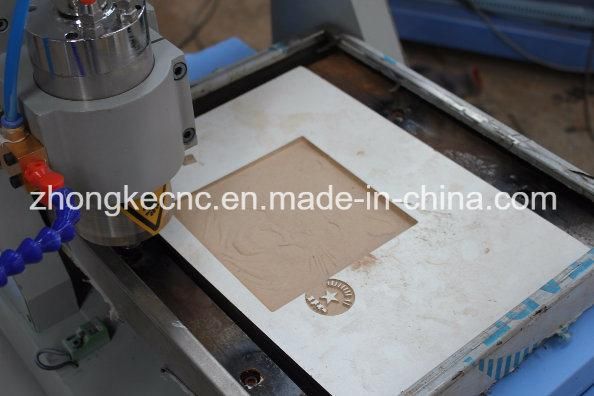

4040 Mini CNC Engraving Amchine

Jinan Zhongke CNC Equipment Co., Ltd.- Carving Material:Copper

- Controlling Mode:CNC

- Main Axle Rotational Speed:≤24000rpm

- Milling Cutter Diameter:10mm

- Feeding Height:150mm

- Certification:CE

Base Info

- Model NO.:4040

- Warranty:12 Months

- Customized:Non-Customized

- Condition:New

- Working Area:400*400mm

- Z Axis Feeding Height:100mm

- Table:Aluminum T-Slot Table

- Control System:Ncstudio Control System

- Inverter:Best Inverter

- Spindle Power:1.5kw

- Spindle Cooling Way:Water Cooling Spindle

- Speed Max:0-100mm,S

- Transmission:Ball Screw

- Table Structure:Casing Iron Bed Structure

- Transport Package:Exporting Plywood Package

- Specification:CE. SGS

- Trademark:ZHONGKE

- Origin:Jinan, China

- HS Code:8465990000

- Production Capacity:1000 Sets Per Year

Description

Model

ZK-6060

X.Y.Z working area

600 X600X120mm

X.Y.Z positioning accuracy

+ 0.005/300 mm

X.Y.Z repositioning precision

+ 0.01 mm

The flatness

+ 0.025/300 mm

X.Y vertical degree

0.025/300 mm

Z to space height

200 mm

Spindle power

2.2 KW

Spindle speed

6000-24000 RPM

Drive system

Steper or servo

Working voltage single-phase

220 V three-phase 380 V / 50 HZ ac + 10 / % (optional)

Machine weight

300 Kg

Note:Optional machine parts

1.The spindle can be water-cooling or air-cooling, single head or multi-head,

And its power can be changed according to the material.(3.0kw, 3.2kw, 4.5kw, 5.5kw etc.)

China brand HQD or Italy HSD spindle.

2.The operation system can be DSP or NC studio system, or MACH3 control system

3.Table surface:Aluminum T-slot table with clamps or vacuum adsorption table with vacuum pump

If you need double use, we also can produce T-slot and vacuum table together

4.The motor can be stepper or servo motor, or hybrid servo motor

5.You can also add dust collector, dust cover, rotary axis, auto oiling lubricating system

6.Other customerized parts.

Cnc router machine manufacturing process:

1.The engineers design the machine according to your needs.

2.The purchasing department carefully select and buy the machine parts.

3.The skilled workers make the machine.

4.The quanlity control department supervise the whole manufacture process.

if you are interested in our machine, welcome to contact with me