Metal Wall Panel Roofing Sheet Cold Roll Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Forging Forming Method:Mold Forging

- Power Source:Electric

Base Info

- Model NO.:Cold Roll Forming Machine

- Feature:Automation

- Certification:ISO9001, CE

- Warranty:12 Months

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Mode:Cold Roll Forming Machine

- Feeding Width:1000 mm

- Finial Product:840-210-25 Trapezoidal Sheet

- Main Motor:4 Kw

- Pump Motor:4 Kw

- Shaft Diameter:75mm

- Forming Steps:13 Rows

- Main Frame:300 H,U Steel

- Forming Speed:8-12 M,Min

- Machine Size:6500mm*1250mm*1400mm

- Transport Package:Waterproof Package

- Specification:DX1000-840-210-25

- Trademark:DIXIN

- Origin:China, Hebei

- HS Code:84552210

- Production Capacity:36 Sets Per Month

Description

Basic Info.

Model NO. Cold Roll Forming Machine Feature Automation Certification ISO9001, CE Warranty 12 Months Customized Customized Advantage Easy to Maintenance Condition New Mode Cold Roll Forming Machine Feeding Width 1000 mm Finial Product 840-210-25 Trapezoidal Sheet Main Motor 4 Kw Pump Motor 4 Kw Shaft Diameter 75mm Forming Steps 13 Rows Main Frame 300 H/U Steel Forming Speed 8-12 M/Min Machine Size 6500mm*1250mm*1400mm Transport Package Waterproof Package Specification DX1000-840-210-25 Trademark DIXIN Origin China, Hebei HS Code 84552210 Production Capacity 36 Sets Per MonthProduct Description

Metal Wall Panel roofing sheet Cold Roll Forming MachineDetails of Parameters

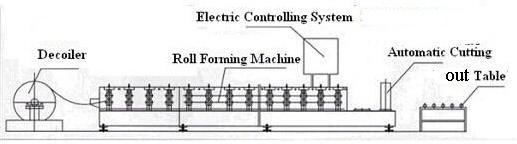

1. Configurations: Manual decoiler, guiding platform, main machine of roll forming, cutting device, output table, electro-motor, hydraulic station, PLC control system

2. Processing material: Aluminium sheet/galvanized steel sheet/color steel sheet

3. Material thickness: 0.3-0.8mm

4. Effective width: 840-210-25 mm

5. Feeding width: 1000 mm

6. Main motor power: 4kw

7. Pump power: 4 kw

8. Shaft diameter: 75mm

9. Forming steps: 13 steps

10. Main frame: 300H steel

11. Medium plate thickness: 14 mm

12. Control system: PLC computer control with inverter

13. Power supply: 380V, 3 Phase, 60Hz

14.0veral sized: 6500mm*1250mm*1400mm

15. Total weight: About 3.0 tons

16. Roller material: High grade NO. 45 forged steel, with hard chrome plating

17. Shaft material: High grade NO. 45 carbon wrought steel

18. Cutter material: Cr12 mould steel with quenched treatment.

Consist of/Whole production line

Manual uncoiler---feeding device---rolling form---speed, length, pieces set by PLC---hydraulic mold post cutting---collection table

| 1 | Direct manufacturer Since 2008 |

| 2 | Golden customer evaluation and complete after-sale service |

| 3 | CE,SGS,BV,TUV-- |

| 4 | Custom design to satisfy trader,factory or personal use |

| 5 | Environmental protection production line ,no harm to environment and animal |

| 6 | Easy communication and feedback,professional advice for free |

| 7 | Engineer service in your factory available and economic |