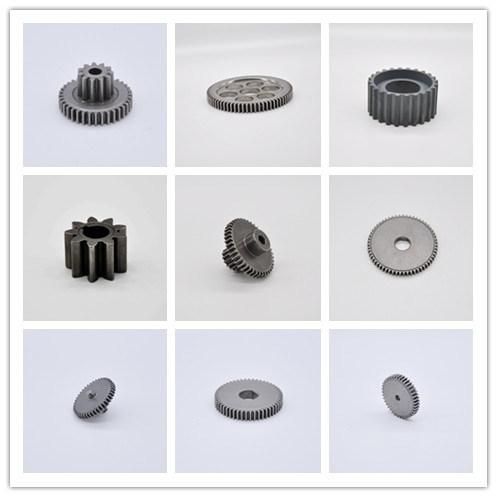

Customized Sintered Powder Tooth Metal Pinion Spur Components Powdered Iron Pm Gear Metal Metallurgy Parts

Shijiazhuang Jingshi New Material Science and Technology Co., Ltd.- Condition:New

- Certification:RoHS, Ts16949

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Iron Alloy Powder

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Density:6.4-7.4 g,cm3

- Transport Package:PE Bag, Bubble Bag, Carton, Pallet

- Trademark:HLXCL

- Origin:China

- Production Capacity:5000000pieces,Year

Description

Basic Info.

Density 6.4-7.4 g/cm3 Transport Package PE Bag, Bubble Bag, Carton, Pallet Trademark HLXCL Origin China Production Capacity 5000000pieces/YearProduct Description

PM metal iron stainless steel powder metallurgy products

| Product Name | High precision gear manufacturers by powder metallurgy |

| Material | Iron powder, alloy powder,precious metal powder |

| Technology | Sintering - Powder Metallurgy |

| Certificate | ISO9001/TS16949 |

| Surface Treatment | High frequency quenching, oil impregnation,CNC,vacuum cleaning,polishing, |

| Apperance | No crumbling, cracks, exfoliation, voids, metal pitting and other defects |

| Process Flow | Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - Packing |

| Application | Motorcycle parts, auto parts, Power Tools parts, Motor parts, electric Bicycle, |

Why Powdered metals?

Significant cost savings.Create complex or unique shapes.

No or minimal waste during production.

High quality finished products.

Strength of materials

Production process of powder metallurgy

Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - Packing

Company Profile

JINGSHI established in 2007

Manufacturer & Exporter

Exacting in producing powder metallurgy gears and parts

Passed ISO/TS16949 Quality Certificate

Advanced Equipment

Numbers senior R & D engineers and Skilled operators

Precise Examination Instruments.

Strict Quality Control

With the "More diversity, More superior, More professional " business purposes, we are committed to establish long-term friendship and win-win relationship with domestic and international customers to create a bright future .

Certification

Please Send us your 2D or 3D drawings to start our cooperation!