Milling Aluminum Precision Part CNC Metal Smoking Pipes Parts Machined Part

SZ LCH INDUSTRY CO., LTD- Condition:New

- Certification:GS, ISO9001

- Customized:Customized

- Material:Brass,Aluminum,Titanium,Stainless Steel etc

- Finish:Anodized ,Sandblasting,etc

- Tolerance:+,- 0.02mm

Base Info

- Model NO.:CNC machined part

- Scrap Rate:1%~2%

- MOQ:100PCS

- Leading Time:10~15days

- Transport Package:EPE

- Specification:ISO9001, SGS

- Trademark:LCH

- Origin:Shenzhen, Guangdong

- HS Code:7616991090

- Production Capacity:500, 000, Year

Description

1.We are True manufacture with competitive price and fast lead time.

2.we have 2 platform:alibaba & made in China,Rich export experience.

3.High quality and best services,Advanced equipment & Professional experience.

Product Description

High Precision! High-End Finish! Excellent Quality! Best Machining!

(1).Material:Brass/ aluminum/iron/Tin/ stainless steel

(2).Surface Finished: Anodize &Sandblasting

(3).Process: CNC Turning

(4).Tolerance:0.02mm

Parts Information:

(1). Applicable Material---Aluminum/zinc alloy, iron, steel alloy, plastic, brass, steel, and stainless steel

(2). Surface treatment---polishing, zinc plating, nickel plating, chrome plating, anodizing.

(3). Payment Terms: 40% deposit before production and 60% balance before arrange shipping

(4). Packaging: Standard package/ Pallet or container/ as per customized specifications.

(5). Shipment Terms: Express & air freight is preferred / sea freight/ as per customized specifications.

We have professional engineers,advanced equipment.more than 5, 000sqm workshop and about 60 sets CNC turning and milling machine make us a modernized and standardized factory. Now we have more than 100 workers, and 5 engineers, as well as 26 professional technicians. Our well-equipped CNC machine workshop has a comprehensive range of precision machining center, milling and turning equipment, all using CNC technology, which enables us to meet the exacting demands of our customers

How we can keep the high quality parts always?

1.All our material will be tested by SGS before production

2. Full control of process:

(1).During the part production,our QC worker will inspect the part size every one hour,this will help us to keep the correct tolerance during production

(2). When the parts machining finished,they will be arranged to have surface finished(such as anodize or powder coated),after that,our QC worker will inspect the parts again,because after surface finished,part tolerance may be difference sometimes,if there is any defective parts we found,we will pick them out directly

(3). Before shipping,our package worker will check the part surface and see if there is any scrach or any other thing that affect the part looking,if yes,pick them out.

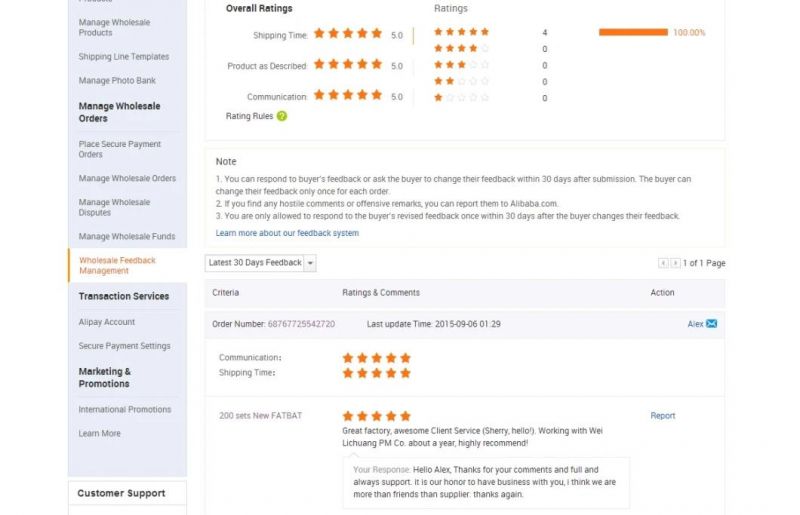

Customer comments

Conclusion

Thanks for your kind attention, looking forward to your inquiry and we ensure tip top quality products with the best lead-time being provided!any questions just feel free to ask me.Welcome to our factory,best wishes to you!