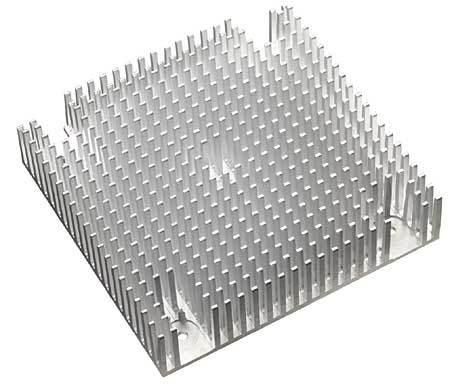

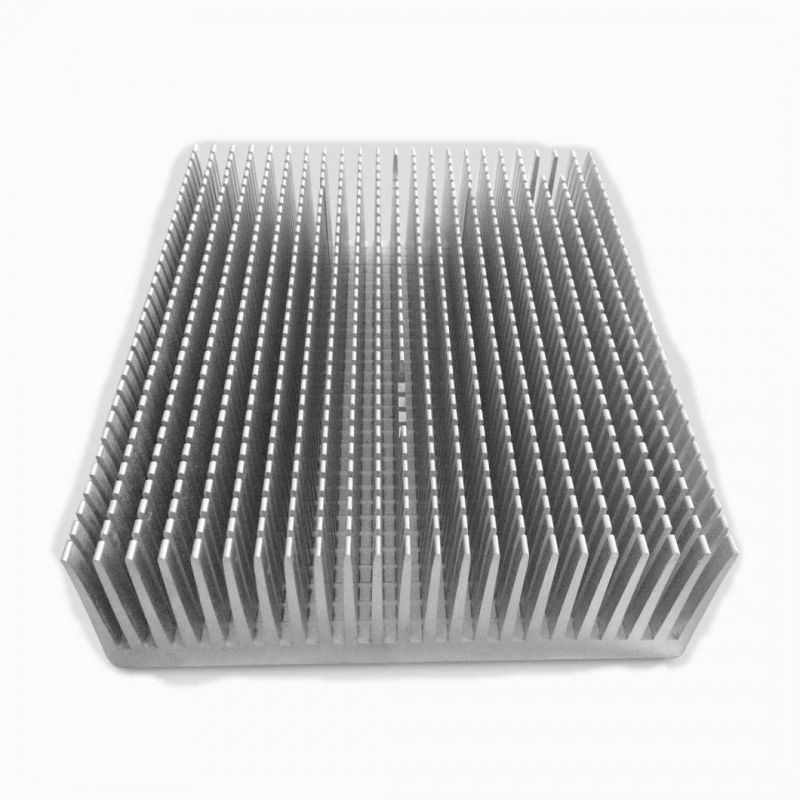

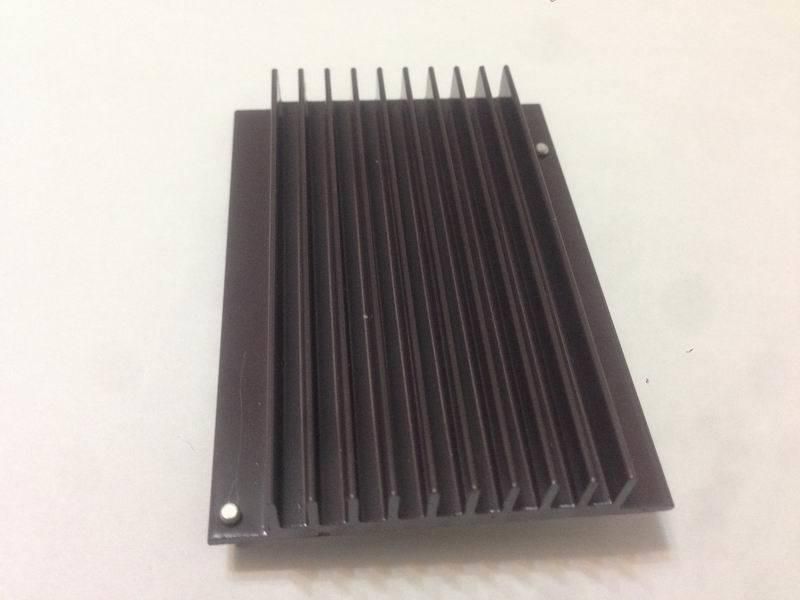

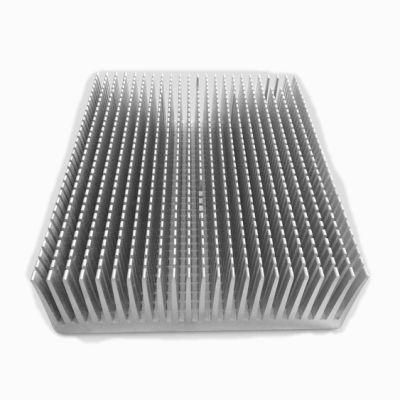

Precision CNC Machining New Aluminum Alloy Skived Heat Sink Industry/Electronic Parts Heat Sinks

Dongguan Quality Innovation and Technology Co., Ltd- After-sales Service:on Line Service

- Warranty:One Year

- Condition:New

- Certification:CE, RoHS, ISO9001

- Standard:DIN, GB, JIS

- Customized:Customized

Base Info

- Model NO.:QIAT-0180

- Material:Aluminum

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Drawing Machinery, Metal Casting Machinery

- Raw Material:Aluminum Alloy,Stainless Steel,Copper

- Processing:CNC Machining,CNC Turning,Drilling,Milling,Brushin

- Surface Treatment:Anodizing,Sand Blasting,Passivation,Galvanizing

- Torlerance:+-0.005mm

- Sample Lead Time:3-5 Working Days

- Terms:Fob,CIF,CFR

- Capacity:100000 PCS Per Month

- Transport Package:Foam+Paper Cartons+Wooden Pallet

- Specification:OEM(According to cleint′s design

- Trademark:NO

- Origin:Made in China

- HS Code:94059900

- Production Capacity:100000 PCS Per Month

Description

Our advantage:

1. Experienced engineering team;

2. Full process QC inspection, complete quality system before, during and after processing;

3. Efficient and rapid response, benign interaction between business and production, and accurately grasp customer requirements;