Factory Provide Hot DIP Zinc Galvanizing Kettle

Hebei Annuo Automation Technology Co., Ltd.- Type:Coating Production Line

- Coating:Galvanized

- Substrate:Steel

- Certification:CE, ISO

- Condition:New

- Material:Steel (Angang Xg08), Ceramic

Base Info

- Model NO.:HDG-K

- Heating Method:Electric, Steam, Hot Water or Other

- Steel Plate Thickness:50mm, 60mm

- Shape and Size:Customized

- Working Life:8-10 Years

- Transport Package:Customized

- Specification:Customized

- Trademark:Annuo

- Origin:Hebei, China

- HS Code:85433000

- Production Capacity:20000 Sets, Years

Description

The features of manufacturing process:

- Steel material arriving at our factory undergoes a thorough inspection of the chemical compositions, to ensure to be upto the mustard.

- Strict quality control, reliable quality. We do 100% Ultrasonic Test to the steel plate and the welding line strictly complying with the national standards GB/T11345-1989.

- Rational use of plate width to reduce the welding line.

- Weld position are as per customer's requirements or as per the characteristics of the furnace, keep away from the heating area.

- The finished galvanizing pot must be Ultrasonic Tested before sending to customers.

- We have passed the CE Certificate.

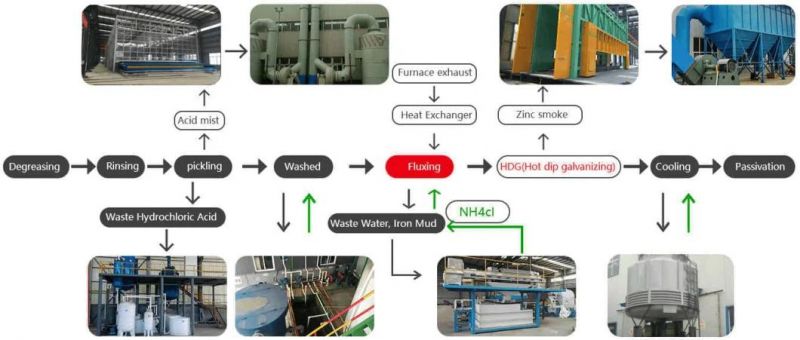

Technical Process for Galvanizing line:

Certificates:

All products are CE Authentication