Professional Metal Fabricatory Metal Welding Bending Products Sheet Metal Bracket Stamp Parts

Kunshan Wangdaxin Precision Mould Technology Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

- Material:Metal

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Model NO.:XA-02

- Product Name:Sheet Metal Bracket

- Process:Sheet Metal Fabrication , Bending, Stamping

- Surface Treatment:Zinc Plated, Oxidation, Black , Sandblasting

- Keyword:Sheet Metal Forming Pressing Part

- Service:Laser Cutting Service

- Applications:Automotive Parts, 3c Products

- Technology:Custom Bending Sheet Metal Parts

- Lead Time:10~15 Working Days

- Usage:Stamping Parts

- MOQ:100PCS

- Transport Package:1PC, Box

- Specification:50X50X50

- Trademark:WDX

- Production Capacity:50000 Piece,Pieces Per Month

Description

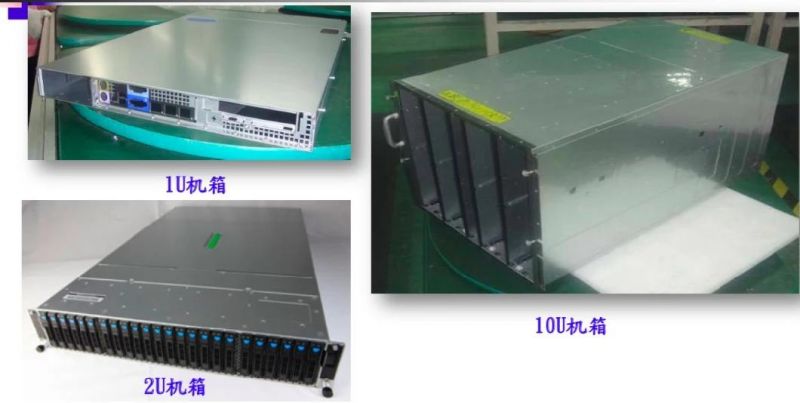

Development of server mould:

Development of server mould:

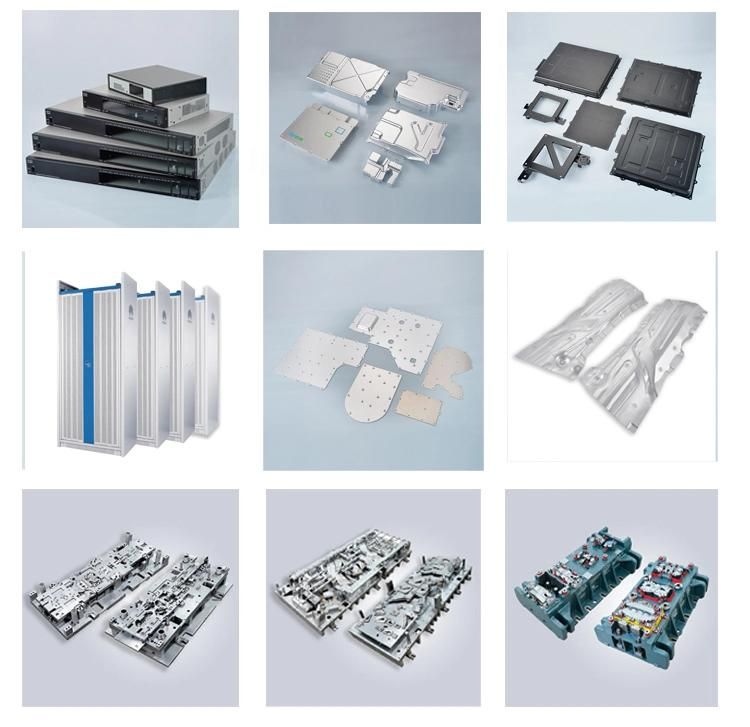

successful cases

VIP Customers

VIP Customers certificate

certificate Protective Packaging Solutions:

Protective Packaging Solutions: FAQ* Are you a factory or trader for sheet metal fabrication and laser cutting services?

FAQ* Are you a factory or trader for sheet metal fabrication and laser cutting services?Wangdaxin are an ISO 9001 certified factory specialized in sheet metal fabrication and laser cutting services.

*Does Wangdaxin have any certifications?

We have ISO 9001: 2015 and ISO 14001 Certifications.

*What services are available?

Our services include laser cutting, punching, shearing, bending, welding, profiling, stamping, insertion, finishing, and assembly.

*How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

* Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

*Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers' privacy of drawings, signing NDA is also accepted if need.

* Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

* How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

* How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

* What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you ASAP.