Industrial Microseism Jolt Squeeze Moulding Machine for Foundry

Qingdao Bestech Machinery Co., Ltd.- After-sales Service:on Line Support

- Warranty:1year

- Colour:Optional

- Price:Discount

- Productivity:Customized

- Worktable Size:Customized

Base Info

- Model NO.:Z14 series

- Business Type:Manufacturer & Trading Company

- Applied Range:Producting Casting Parts

- Transport Package:Wooden Box or Iron Frame

- Specification:Z14

- Trademark:BESTECH

- Origin:Qingdao Shandong

- HS Code:8424300000

- Production Capacity:500sets

Description

Basic Info.

Model NO. Z14 series Business Type Manufacturer & Trading Company Applied Range Producting Casting Parts Transport Package Wooden Box or Iron Frame Specification Z14 Trademark BESTECH Origin Qingdao Shandong HS Code 8424300000 Production Capacity 500setsProduct Description

Company Information:

QINGDO BESTECH MACHINERY CO.,LTD own the strong development real strength, the forerunner's production craft, perfect examination means, the management system of science. The conduct and actions casts the professional production factory house, technique, quantity and the automation level etc. of the machine profession to all be placed in the domestic to go together the advanced level of industry.

Jolt Squeeze Molding Machine

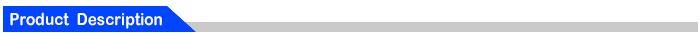

1.The machine suitable for batch production of small size molding piece single faced plate and single box

mode,up box and down box be made.The machine adopt spring microseism pressing structure,pressing

cylinder wide,pressing strength strong is good for molding quality,pneumatic pipe simple,easy control and

convenience.

2.It is fully buffered,high-frequency,low amplitude,pneumatic-type molding machine microseism

compaction.It used a buffer spring,pneumatic microseism institutions can reduce the shock impact of the

foundation.All parts of the aircraft fuselage steel,a substantial increase of steel.

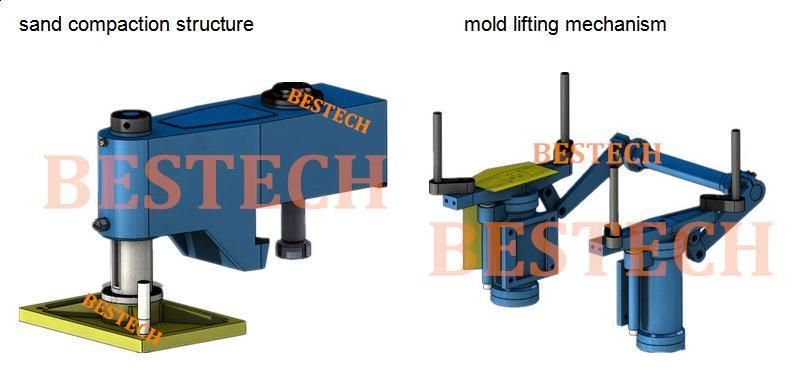

3.The microseism structure with aircraft body table,shock pistons,shock compaction iron piston,cylinder

and compaction.Mode since the aircraft structure,by the connecting rod from cylinder mode axis

synchronization,push mode,such as starting composition.Cylinder adopt air pressure control mode to

ensure a smooth beginning.

4. Sand mold casting pouring thin-wall castings, precise size, smooth surface.

| Name | UNIT | Z143W | Z145W | Z146W | Z148W |

| The Max. dimension of Sand Box | mm | 400*400*100 | 500*4500*200 | 600*500*200 | 800*630*300 |

| Worktable/ Workbench dimension | mm | 560*420 | 600*460 | 550*700 | 900*730 |

| Compressive stress | kgf | 4200 | 5500 | 7500 | 10000 |

| Compress process | mm | 100 | 160 | 200 | 280 |

| Drawing mould process | mm | 160 | 200 | 200 | 320 |

| Distance compacting plate with worktable | mm | 200-370 | 300-450 | 350-450 | 680 |

| Productivity | mould/h | 40-60 | 40-60 | 40-60 | 40-60 |

| Out line dimension L*W*H | mm | 950*680*1280 | 1200*1000*1693 | 1380*850*1565 | 1600*1038*2200 |

Packing& shipping

If you are any interested in our foundry machinery , Please contact us freely .

Warmly welcome to visit our factory! Our team waiting you for here!