Botou Light Steel Keel Metal Furring Omrga House Structure Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Type:Hydraulic Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:Automation

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:Customized

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Mode:840-210-25 Roof Tile Machine

- Auto:Fully Automatic

- Feeding Material:Metal Coil

- Feeding Width:1000mm

- Feeding Thickness:0.25-0.7mm Thickness

- Production Speed:4-6m,Min

- Roll Forming Speed:8-12m,Min

- Control Systerm:PLC Computer Control with Inverter

- Size:6500mm*1500mm*1500mm

- Weight:3.2 Tons

- Transport Package:Waterproof Package

- Specification:CE SGS ISO

- Trademark:DIXIN

- Origin:China, Hebei

- HS Code:84552210

- Production Capacity:50 Sets Per Month

Description

light gauge steel framing machine

Loading capacity

1.5T

Uncoiling width

300mm

Inner diameter

450-550mm

Length of the main part

3000*800*1400mm

Weight of main part

3T

Voltage

380V/50HZ 3Phase

Roller fixer

middle plate

Frame

350H steel

Drive mode

chain or gear

Material of rollers

45#steel, surface hard chromium plating

Material of shafts

45#steel

Diameter of shafts

40mm

Number of rollers

10 rollers

Main power

3kw

Material of mould

Cr12 quenched

Power supply

hydraulic power

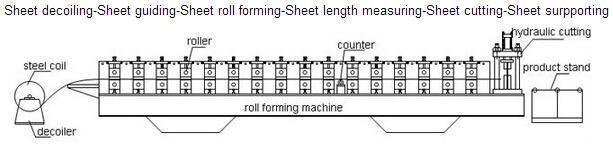

Working flow

Components of line

(1) Manual Decoiler (Max.Capacity:2T Coil Inner-Diameter: 508mm)

(2)Roll-Forming M/C (Just for your reference, will make the machine as your drawing)

(3) Cutting Mechanism

It adopts hydraulic motor drive and automatic location to decide the dimension and cut the target products.

(4) Hydraulic System

Match equipment: a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

Hydraulic pump power: 3KW

(5)Computer control cabinet :

1). Screen: DELTA screen from Taiwan

2) PLC: DELTA

3). Automatic length measurement

4). Automatic quantity measurement

5).Computer is used to control length and quantity. Machine will automatically cut to length and stop when required quantity is achieved

(6)Counter

One counter gauges length, pulses, and decides length.

(7)Output table (3M one set)

About our company

Our service

1.We have professional team to make different kinds of roll forming machines for our customers, from designing, processing,assembling, debugging, delivery.

2.we can send our engineer to your site and do the training for your men. you just only bear the cost for our engineer's air ticket,visa,accormadation,food and transpotaion in your country.

3.You can send your men to our factory. we will teach them how to operate the machine without training charges.

4.Actually theres another cheap and easy way to choose. Every machine leave our factory with one book of operation manual. You can read through the manaul first ,and get familiar with the machine. Then we can get a video call,and teach you on-line how to operate the machine.

5.Apart from above training course,we also provide 1 year warranty for all the easily broken part of the machine for free and whole-life technical service support.

If there is any problems happened to the machine, we will provide solution at once.

Hope we could establish win-win business relations in the soon future!