Steel Plate 0-45 Beveling Machine Automatic I / V Groover CNC Groove Cutter, Plasma 3D Bevel Cutting Machinery, Can Additionally Equip with Laser or Flame Torch

Wuhan Lan-Sun Technology Co., Ltd.- After-sales Service:Yes

- Warranty:12months

- Customized:Customized

- Layout:Vertical

- Cutting Material:Copper, Carbon Steel, Iron, Aluminum, Metal Alloy, Stainless Steel

- Automatic Grade:Automatic

Base Info

- Model NO.:ZLQ-UR

- Power Source:Electric

- Cutting Mode:Laser,Plasma,Flame

- Application:Steel Plate Beveling Cutting

- Control System:Beijing Star Fire Sf-5210s-Pk

- Cutting Shape:Vertical or Bevel

- Beveling Angle:0~45degree

- Cutting Size:Customizable

- Cutting Thickness:0~200mm, Please Refer to Cutting Thickness Table

- Cutting Torch:Can Equip with 2 or More Torches

- Laser Brand:Raycus,Max,Feibo

- Laser Power:1000W~20000W

- Plasma Brand:Huarong,Huayuan,Hyperthem

- Plasma Current:65A,85A,120A,200A,300A,400A,500A

- Flame Gas:Oxy& Acetylene,Propane

- Drive Mode:Servo Motor

- Work Voltage:220V,380V,415V

- Certification:CE&ISO

- Transport Package:Seaworthy Wooden Cases

- Specification:Customizable

- Trademark:LANSUN

- Origin:China

- HS Code:8456401000

- Production Capacity:5000 Sets,Year

Description

A) The positioning accuracy and repeatability of the whole equipment: in line with the JB/T5102-1999 standard

B) Cutting dimensional accuracy, cutting surface quality: in line with JB/T10045.3-1999 standard13 Straightness 0.5mm 14 Roundness 0.5mm 15 Diagonal difference ±0.5mm 16 Rotary axis positioning accuracy ±1.5° 17 Cut surface quality (roughness)

(Select δ=25 plate) Rz(um)=70+1.2a

Visual inspection: roughness 12.5

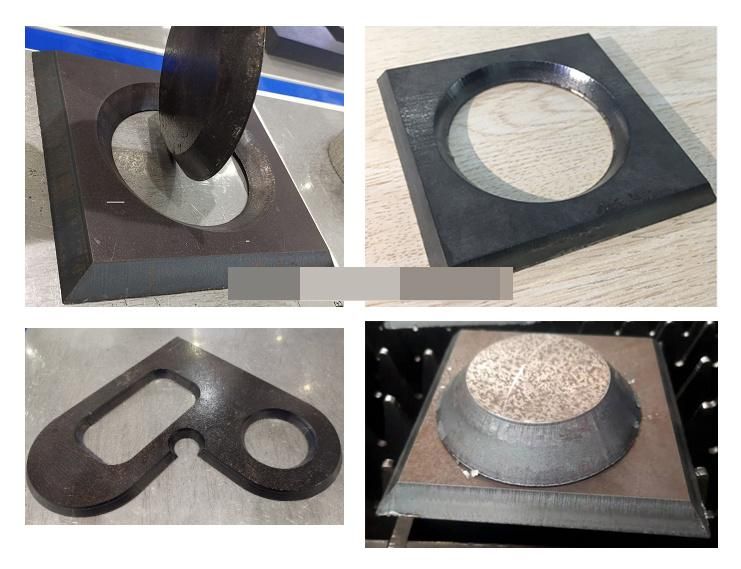

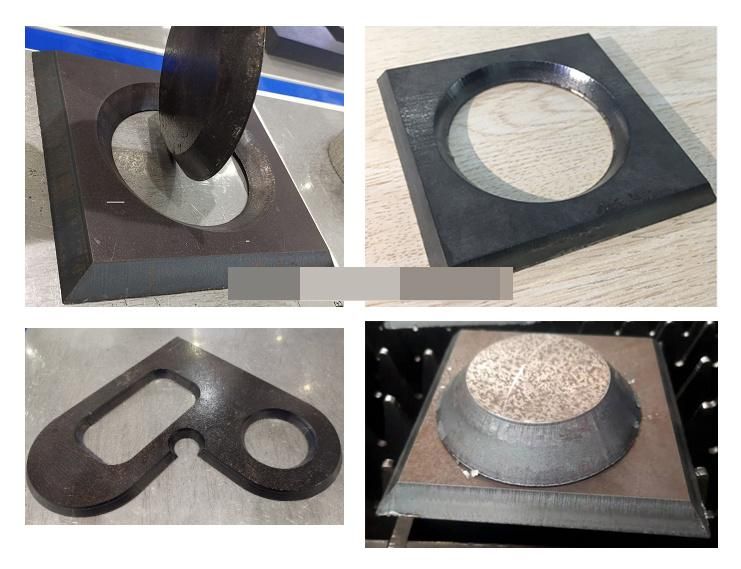

Cutting samples

Packing & ShippingMachines will be packed in seaworthy wooden cases strengthed by metal straps.We can ship to your carrier in China or deliver to your oversea destination.

Why choose us Wuhan Lansun was established by leading experts and Engineering faculty from the China University of Geosciences,and has been specializing in design and manufactur of CNC cutting & welding machines for over 30 years. Our headquarter is located in the Wuhan East Lake High-Tech Development Zone.Lansun covers an area of 42 acres, and has 27000 square meters of facilities.We can manufacture 20pcs of machines per day. Our sales and service networks are throughout China and oversea.

Lansun has been designated as the base of teaching & research for the School of Mechanical Engineering and Electronic lnformation,China University of Geosciences. Our highly experienced R&D team keeps Lansun leading on the latest CNC cutting&welding technology,and continually launching leading machines

into market. Besides ISO,CE certification,our company also obtains a lot of inventation patents and software copyrights on CNC mechanism and controlling system.

Besides ISO,CE certification,our company also obtains a lot of inventation patents and software copyrights on CNC mechanism and controlling system.

FQA

FQA1. Are you a factory or trading company?

B) Cutting dimensional accuracy, cutting surface quality: in line with JB/T10045.3-1999 standard

(Select δ=25 plate)

Visual inspection: roughness 12.5

Cutting samples

Packing & ShippingMachines will be packed in seaworthy wooden cases strengthed by metal straps.We can ship to your carrier in China or deliver to your oversea destination.

Why choose us Wuhan Lansun was established by leading experts and Engineering faculty from the China University of Geosciences,and has been specializing in design and manufactur of CNC cutting & welding machines for over 30 years. Our headquarter is located in the Wuhan East Lake High-Tech Development Zone.Lansun covers an area of 42 acres, and has 27000 square meters of facilities.We can manufacture 20pcs of machines per day. Our sales and service networks are throughout China and oversea.

Lansun has been designated as the base of teaching & research for the School of Mechanical Engineering and Electronic lnformation,China University of Geosciences. Our highly experienced R&D team keeps Lansun leading on the latest CNC cutting&welding technology,and continually launching leading machines

into market.

Besides ISO,CE certification,our company also obtains a lot of inventation patents and software copyrights on CNC mechanism and controlling system.

Besides ISO,CE certification,our company also obtains a lot of inventation patents and software copyrights on CNC mechanism and controlling system.

FQA

FQA