OEM Aluminum Parts Services CNC Aluminium Milling Parts

Shenzhen Mingxiang Hardware Technology Co., Ltd.- Certification:CE, RoHS, ISO9001

- Customized:Customized

- Material:Aluminum, Cooper, Brass,Iron ,POM,Steel Alloys,Sta

- Application:Metal Recycling Machine, Metal Processing Machinery Parts

- Logo:Customized Logo

- Keyword:CNC Machining Parts

Base Info

- Model NO.:cnc aluminum parts

- Drawing Format:Pdf,Dwg,Igs,STP etc

- Color:Customized Color

- Service:OEM,ODM CNC Machining as Per Customer′s Requiremen

- Payment:T,T Credit Card

- QC Control:100% Inspection Before Shipment

- Tolerance:+-0.01mm(Custom Available)

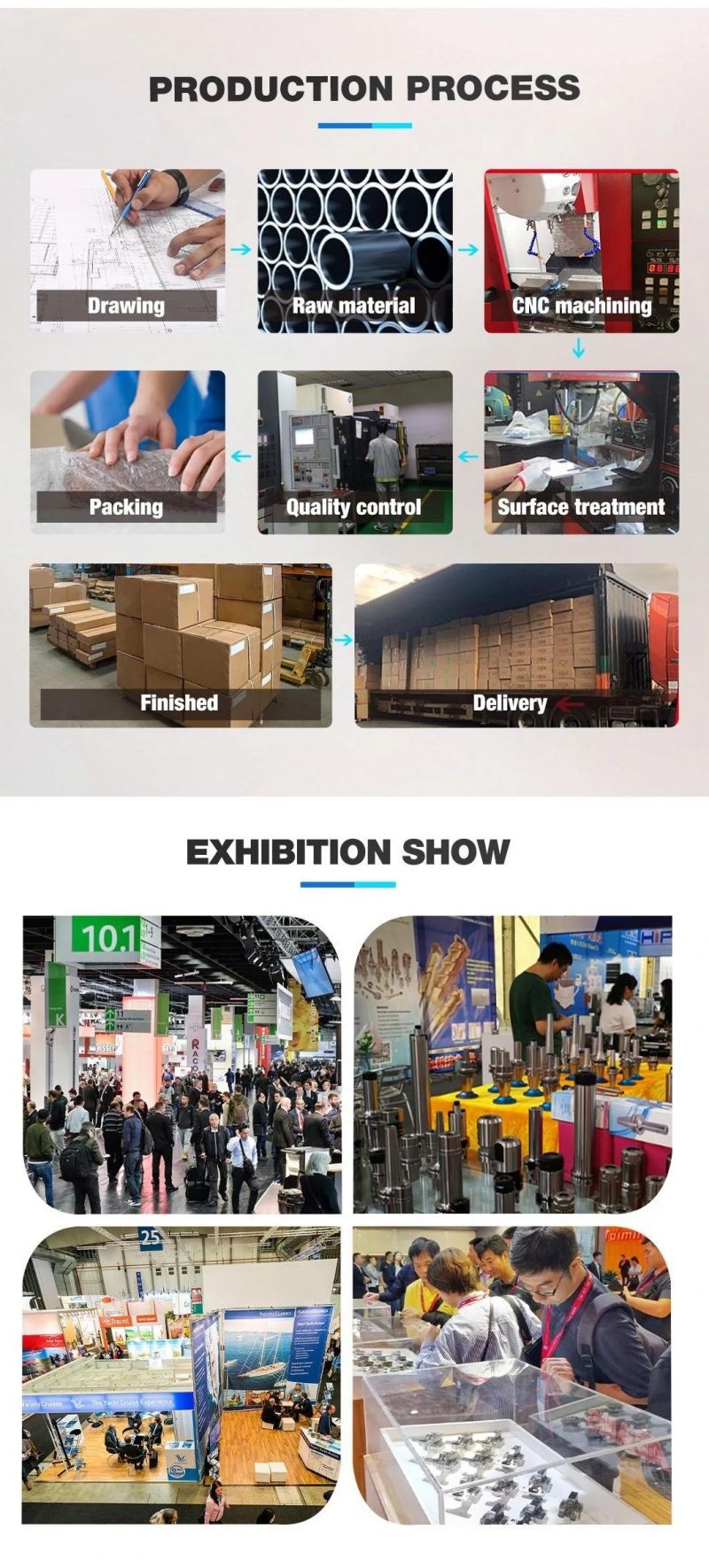

- Process:CNC Milling

- Transport Package:Packed in Cartons or Wooden Crate.

- Origin:China

- Production Capacity:500000,Year

Description

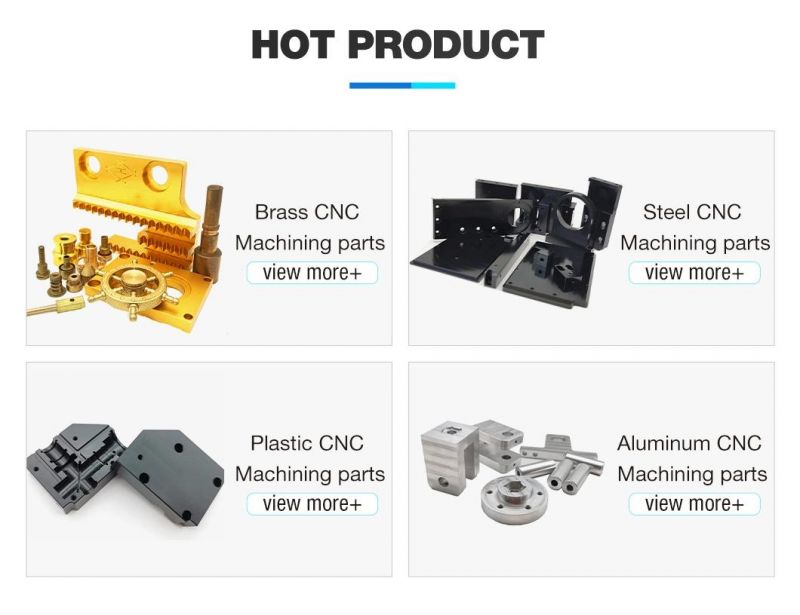

Hot product

Hot product

FAQ

Q:What do I need for offering a quote?

A: Please offer us 2D or 3D drawings (conclude materials,dimension,tolerance,surface treatment or other technical requirement),quantity,application,or samples.Then we will quote the best price within 24 hours for you.

Q:How about the MOQ?

A:MOQ depends on your need ,besides,we welcome trial order before mass-production.

Q:What is the product cycle?

A:It varies a lot depending on product dimension,technical requirement and quantity.We always try to meet customer's requirement by adjusting our workshop schedule.

Q:What kind of payment terms do you accept?

A:T/T,Credit Card

Q:Is it possible to know how is my product going on without visiting our company?

A:We will offer a detailed products schedule and send weekly reports with digital pictures and vedios which show the machining progress.