High Speed Dry Type Straight Line CO2 Gas Shielded Copper Coated Welding Wire (ER70S-6) Production Line

TIANJIN BEEST INTERNATIONAL LIMITED- Type:LZ Straight-Line Metal Drawing Machine

- Usage:Wire, Rope Wire, Prestressed Steel Wire, Standard Parts, Copper Coated Welding Wire

- Metal Material:Steel

- Outlet Diameter:0.8 1.2 1.6

- Max.Inlet Wire Dia.:6.5mm

- Block Dia.:560mm

Base Info

- Model NO.:FSSJ1000A+ZQW1,560+ ZQ5,560+7,450+SG800

- Max. Number of Block:15

- Certification:REACH, RoHS, ISO

- Condition:New

- Use for:H,M,L Carbon Steel Wire

- Motor Type:Servo Motor

- Gear Box:No Gear Box

- Cabinet Cooling:Water Cooling

- Max Speed:30m,S

- Stop Time:3s

- Transport Package:Container

- Specification:7.5kw--132kw

- Trademark:Beest

- Origin:China

- HS Code:846310

- Production Capacity:30000t,Year

Description

Motor power22kw Capstan 1#-13# 37kw Bobbin take up Drawing die dimension Φ 35 mm * 44 mm Machine working direction Left or right inlet Operator face machine, left hand side is pay off stand, right side is take up machine side,this is left inlet machine, otherwise, it is right inlet machine; Machine color Machine main: gray RAL7024;

Cover: gray RAL7035; Rotating parts: Red RAL3000 Productivity

Productivity each line: 4000 tons per year

Inlet /6.5/5.5mm, output 1.2 mm,

working time: 20 hours per day, 300 days per year) 22kw Capstan 1#-15# 37kw Bobbin take up

Drawing die dimensionΦ 35 mm * 44 mm

Machine working direction Left or right inlet ,,;,;

Operator face machine, left hand side is pay off stand, right side is take up machine side,this is left inlet machine, otherwise, it is right inlet machine;

Machine color:RAL7024;

:RAL7035;

:RAL 3000

Machine main: gray RAL7024;

Cover: gray RAL7035; Rotating parts: Red RAL3000

Productivity

Productivity each line: For 1.2mm is around 4000tons; 1mm around 2500 tons;0.8mm around 1600 tons per year:5.5mm,:0.8mm,

20,300.

Inlet 5.5mm, output 0.8 mm,

working time: 20 hours per day, 300 days per year)

5,Constituent part:

MIG Wire integrated production line Schematic plot

6,Equipment advantages:

A) Innovated MIG Wire drawing & Copper coating line ;

B)High efficient straight in electrical-chemical copper coating process;

C)With rotating pressure dies, suitable for high speed drawing ;

D)Fully auto the confecting solution, according to the checking datas fully auto to mix the liquid to centain concentration the line needed;

E)Fully auto adding &discharing system, according to the results of analysis;

F)Integrated degreas device and high pressure water cleaning device;

G)Integrated pickling device and straight in electrical-chemical copper coating device;

H)Full digit control power of pickling and coating accurately, copper layer more stable ;

I)Five times high pressure water cleaning, antirust more better;

J)full digit control of straight in high frequency drying , get high quality products;

k)Lubrucant by oil in polishing block, with heating and cooling system for lubricant oil....

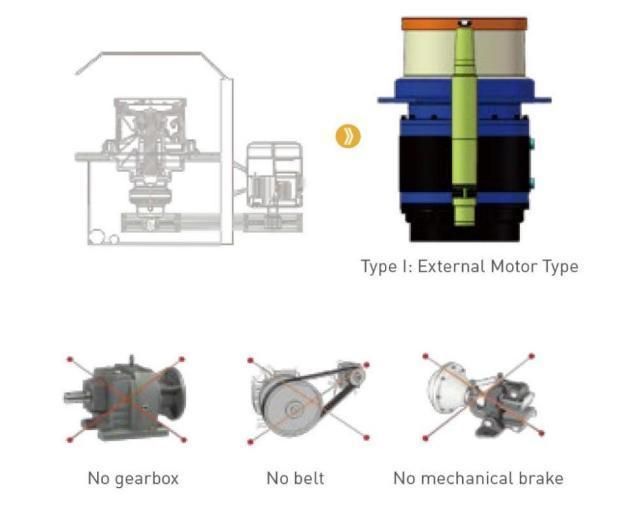

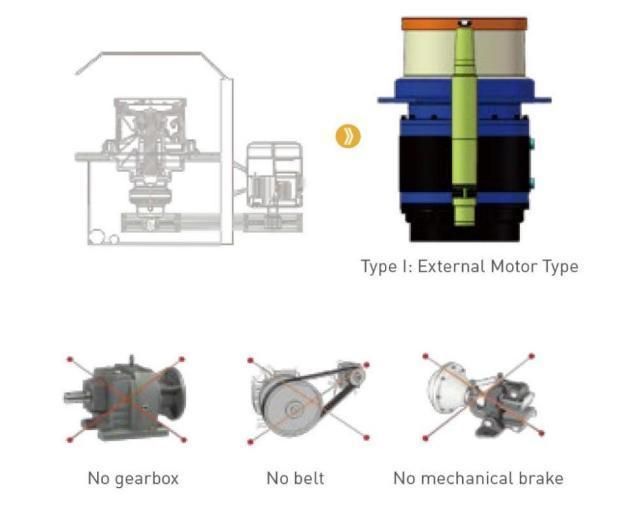

7,Innovative technologies

Servo direct drive technology pioneer, leading technology, the world's first, the cumulative production of direct drive wire-drawing machine more than 500 sets, more than 5000 direct drive motor!

7.1 Servo motor drive directly

Without gear box ; Without transmission belt ; Without mechanical break .

Comprehensive energy saving 10%-20%

The electrical cabinet and machine is integrated

The control panel is on top of electrical cabinet

Preventing damage of motor due to over temperature

Comprehensive energy saving of 10%- 20%

Direct drive environment is quieter

Seal + own dust removal system

Cover: gray RAL7035; Rotating parts: Red RAL3000

working time: 20 hours per day, 300 days per year)

Design Parameters 2

Motor powerDrawing die dimension

Machine working direction

Operator face machine, left hand side is pay off stand, right side is take up machine side,this is left inlet machine, otherwise, it is right inlet machine;

Machine color

:RAL7035;

:RAL 3000

Machine main: gray RAL7024;

Cover: gray RAL7035; Rotating parts: Red RAL3000

Productivity

Productivity each line: For 1.2mm is around 4000tons; 1mm around 2500 tons;0.8mm around 1600 tons per year

20,300.

Inlet 5.5mm, output 0.8 mm,

working time: 20 hours per day, 300 days per year)

5,Constituent part:

MIG Wire integrated production line Schematic plot

6,Equipment advantages:

A) Innovated MIG Wire drawing & Copper coating line ;

B)High efficient straight in electrical-chemical copper coating process;

C)With rotating pressure dies, suitable for high speed drawing ;

D)Fully auto the confecting solution, according to the checking datas fully auto to mix the liquid to centain concentration the line needed;

E)Fully auto adding &discharing system, according to the results of analysis;

F)Integrated degreas device and high pressure water cleaning device;

G)Integrated pickling device and straight in electrical-chemical copper coating device;

H)Full digit control power of pickling and coating accurately, copper layer more stable ;

I)Five times high pressure water cleaning, antirust more better;

J)full digit control of straight in high frequency drying , get high quality products;

k)Lubrucant by oil in polishing block, with heating and cooling system for lubricant oil....

7,Innovative technologies

Servo direct drive technology pioneer, leading technology, the world's first, the cumulative production of direct drive wire-drawing machine more than 500 sets, more than 5000 direct drive motor!

7.1 Servo motor drive directly

7.2 Servo motor connect capstan directly

Without gear box ; Without transmission belt ; Without mechanical break .

Comprehensive energy saving 10%-20%

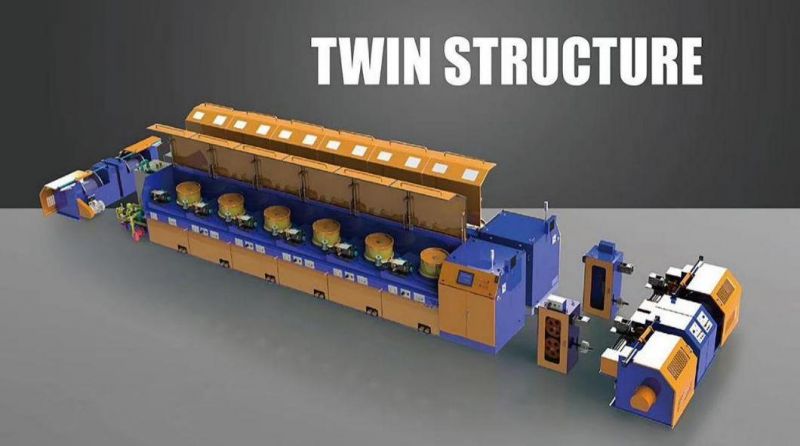

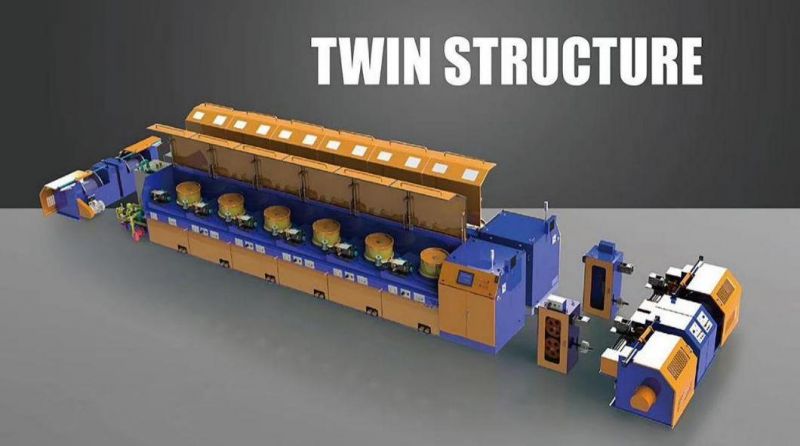

7.3 Twins design

- Two machine can be installed , operate, and maintain back to back

- Twins take up spooler, motor is at inner side

- Save land 50%

- Saving infrastructure

- Save supporting facilities

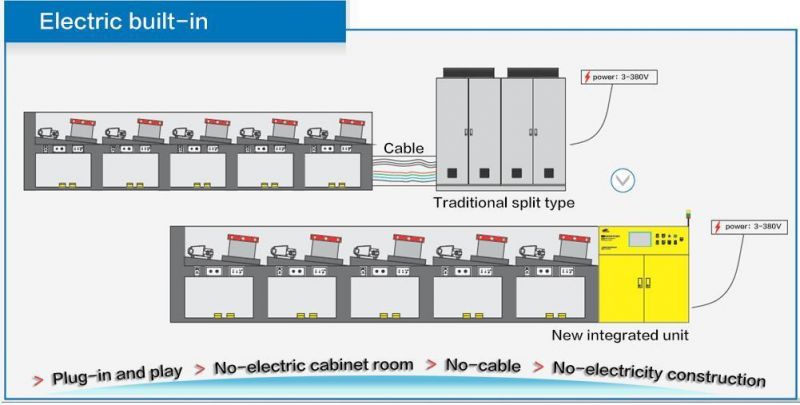

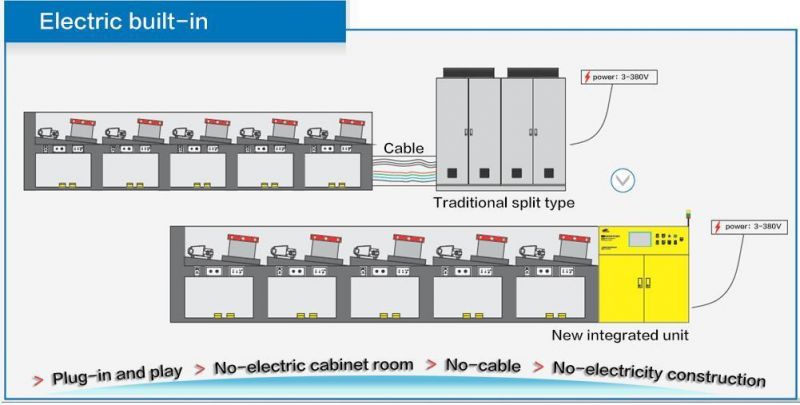

7.4 Plug and play:

The electrical cabinet and machine is integrated

The control panel is on top of electrical cabinet

7.5 Checking temperature of bearing of motor:

Checking the temperature of up and down bearing of motor ,Showing the temperature on time,Making alarm and stop machine for over temperature7.6 Motor and electrical cabinet is cooled by cooling water:

- set independent soft water tank, motor and electrical cabinet is cooled by closed cooling water circulation.

- anti-dust electrical cabinet.No deposit, no block on pipe of cooling water for motor.

7.7 special treatment on inner side of motor:

anti-water, prevention of moisture condensationPreventing damage of motor due to over temperature

7.8 Capstan:

- Adopt bongrace type, avoid drawing powder drop into water plate from gap between frame and capstan

- Capstan is dynamic balanced

7.9 Die Box:

- Pressure type die + rotating die+ powder stirrer

- Pressure type die +powder stirrer

- Forced lubricant,take enough powder on wire surface

7.10 Dust collection system (option):

Can take out drawing powder dropped on frame, it is also helpful for cooling wire7.11 Cooling water flow check:

Equip cooling water counter meter, check cooling water flow accurately7.12 ID register:

Equip ID register device, to run machine, operator should register first. So machine can count quantity of production according to operator7.13 Spare parts is module design:

Standardization of components,Splicing of components,easy maintain7.14 Energy conservation and environmental protection

Comprehensive energy saving of 10%- 20%

Direct drive environment is quieter

Seal + own dust removal system

7.15 Internet of Things

8.Water and electrical configuration requirements

| power supply | 380±10%,50HZ, three-phase five-wire (ground reliable grounding), power configuration and cable specifications as shown in the basic diagram 380±10%,50HZ. |

| air supply | Pressure ≥ 0.5 MPa |

| cooling water | Pressure ≥ 0.08mpa, water temperature ≤25ºC |